Products and systems designed as the foundation of your future

Your water access project speaks for itself. What visitors, residents and partners see when they pull in is a direct reflection on what they’ll expect from you. That’s why when you partner with Marina Technologies, you know that your facility is designed from the water up to impress.

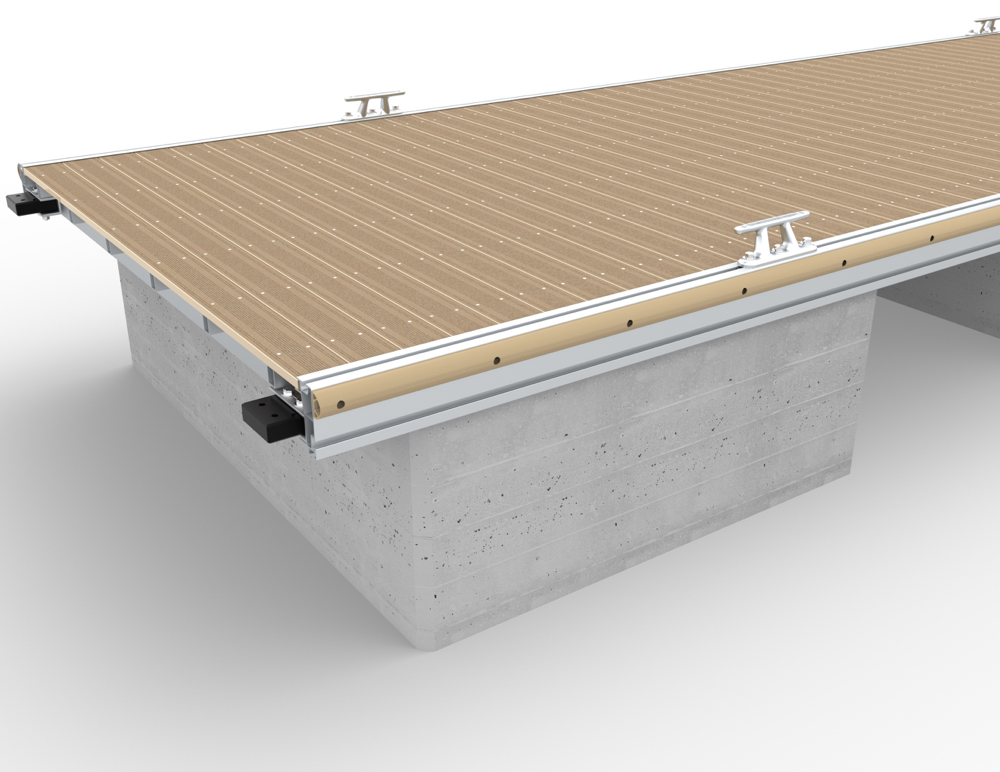

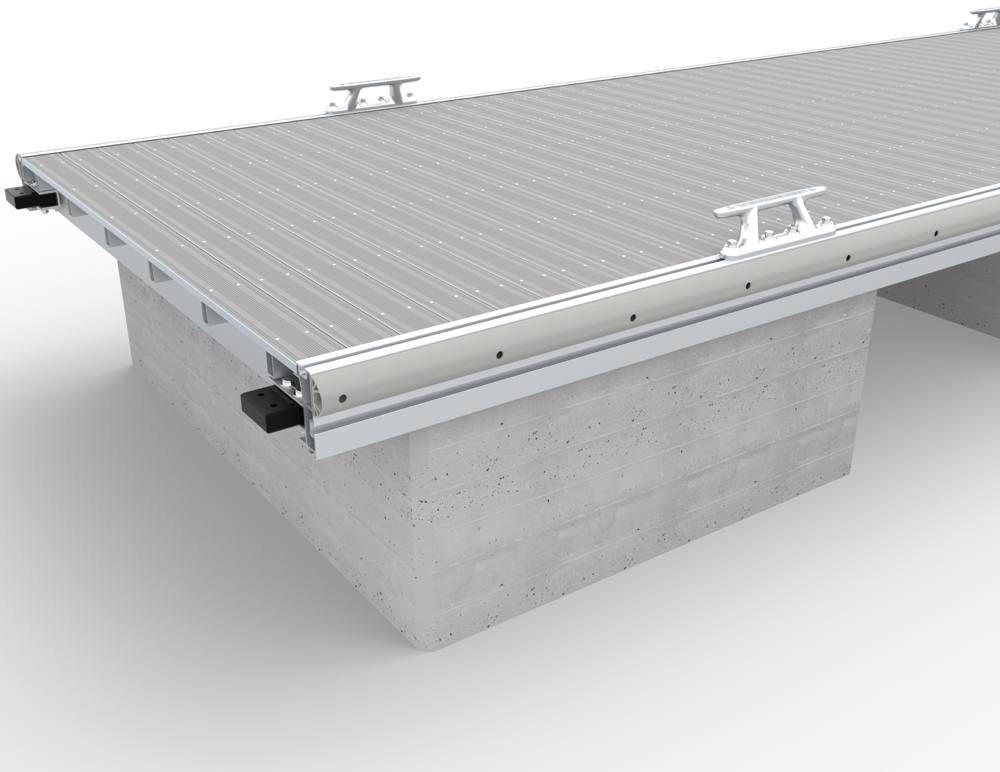

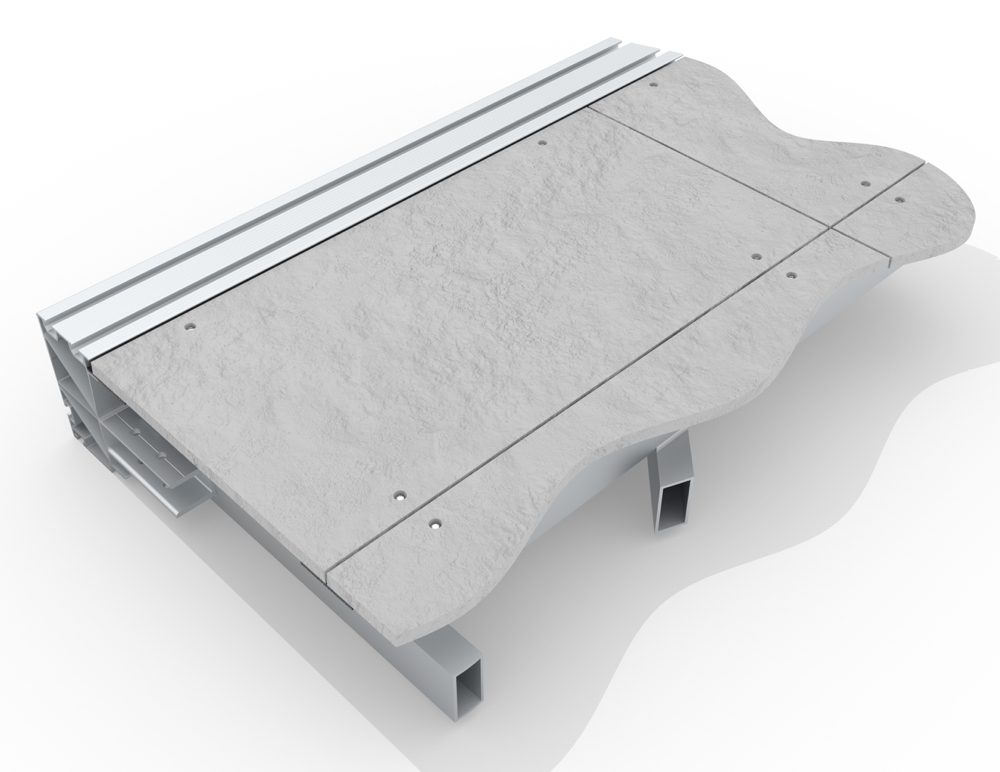

SUPER DUTY SERIES CONCRETE DOCKS

The MTI high strength reinforced single cast concrete dock system offers you a level of strength, durability and stability that elevates your marina to the next level.

Our Super Duty Series Concrete Dock systems are designed and engineered to perform where others fail. From tropical storms/ hurricanes to extreme ice conditions, the Super Duty Series does it all. Super Duty dock sections are typically 40’, 50’ and 60’ long and can also be customized.

Each massive unit connects together using a dual flexible single-bolt connection system on each side making it the strongest system in the industry. This connection system is virtually maintenance free, quick to install and engineered to last for decades to come. Super Duty main docks are typically 6’, 8’, 10’, and 12’ wide. Single piece finger piers are typically 4’, 5’, 6’ and 8’ wide and can be up to 60’ long.

MTI Super Duty Series Concrete Docks are built extremely strong and only use high strength concrete (6,000 Psi) with internal HDG steel reinforcing rebar and wire mesh. Stainless steel sockets are cast into the concrete and tied to the internal steel reinforcement, providing high loading capabilities for fender and cleat mounting.

KEY Benefits:

- Remarkable proven strength, durability and stability.

- Quick and easy installation.

- Designed to last over half a century with very little maintenance.

- Standard 18” freeboard.

- Internal utility routing via sleeves and or single or dual top-access utility troughs.

- Your choice of composite, rubber, vinyl or wood fenders.

- Proven flexible connections designed for rough water conditions.

- No hi-maintenance cables, timber, walers or thru-rods.

- Top-access, internal connection boxes for chain or flexible anchoring systems.

- Internal or external pile guides in either HDG steel or 316L stainless steel.

MEGA-YACHT SERIES CONCRETE DOCKS

The MTI Mega-Yacht series offers a higher 24” freeboard. This massive single cast all reinforced concrete pontoon with HDG internal steel rebar and wire mesh makes it the strongest structural system available today. Designed and engineered for hurricane force winds and waves, the Mega-Yacht series survive where other systems fail.

Mega-Yacht dock sections are typically 40’, 50’ and 60’ long and can also be customized. Each massive unit connects together using our dual flexible single-bolt connection system on each side making it the strongest system in the industry. Mega Yacht main docks are typically 10’, 12’, 14’, 16’, 18’ and 20’ wide. Single piece finger piers are typically 5’, 6’, 8’, 10’and 12’ wide and can be up to 60’ long.

MTI Mega-Yacht Series Concrete Docks are built extremely strong and only use high strength concrete (6,000 Psi) with internal HDG steel reinforcing rebar and wire mesh. Stainless steel sockets are cast into the concrete and tied to the internal steel reinforcement, providing high loading capabilities for fender and cleat mounting.

KEY Benefits:

- Remarkable proven strength, durability and stability.

- Quick and easy installation.

- Designed to last over half a century with very little maintenance.

- Standard 24” freeboard.

- Internal utility routing via sleeves and or single or dual top-access utility troughs.

- Your choice of composite, rubber, vinyl or wood fenders.

- Proven flexible connections designed for rough water conditions.

- No hi-maintenance cables, timber, walers or thru-rods.

- Top-access, internal connection boxes for chain or flexible anchoring systems.

- Internal or external pile guides in either HDG steel or 316L stainless steel.

WAVE ATTENUATOR SERIES CONCRETE DOCKS

The MTI Wave Attenuator Series dock is designed and engineered to protect your marina from the harsh environment and calm the waters. They can also be used for transient or permanent moorage, generating extra revenue while protecting your investment.

The Wave Attenuator Series is made of high strength reinforced single cast concrete and offers a level of attenuation, strength, durability and stability that elevates your marina to the next level. Our Wave Attenuator Series Concrete Dock systems are designed and engineered to perform under extreme conditions.

Wave Attenuator dock sections are typically 40’, 50’, 60’ and 65’ long and can also be customized. Each massive unit connects together using a dual flexible single-bolt connection system on each side making it the strongest system in the industry. Wave Attenuator main docks are typically 10’, 12’, 14’, 16’, 18’ and 20’ wide. Single piece finger piers are typically 5’, 6’, 8’, 10’and 12’ wide and can be up to 60’ long.

MTI Wave Attenuator Series Concrete Docks are built extremely strong and only use high strength concrete (6,000 Psi) with internal HDG steel reinforcing rebar and wire mesh. Stainless steel sockets are cast into the concrete and tied to the internal steel reinforcement, providing high loading capabilities for fender and cleat mounting.

KEY Benefits:

- Remarkable proven strength, durability and stability.

- Quick and easy installation.

- Designed to last over half a century with very little maintenance.

- Standard 24” - 28” freeboard.

- Internal utility routing via sleeves and or single or dual top-access utility troughs.

- Your choice of composite, rubber, vinyl or wood fenders.

- Proven flexible connections designed for rough water conditions.

- No hi-maintenance cables, timber, walers or thru-rods.

- Top-access, internal connection boxes for chain or flexible anchoring systems.

- Internal or external pile guides in either HDG steel or 316L stainless steel.

BREAKWATER SERIES CONCRETE DOCKS

The MTI Breakwater Series docks are designed and engineered to protect your marina from the harsh environment and calm the waters. They can also be used for transient or permanent moorage, generating extra revenue while protecting your investment.

The Twin-Keeled Breakwater Series are made of high strength reinforced single cast concrete and offer a level of attenuation, strength, durability and stability that elevates your marina to the next level. Our Breakwater Series Concrete Dock systems are designed and engineered to perform under extreme conditions.

Breakwater dock sections are typically 40’, 50’, 60’ and 65’ long and can also be customized. Each massive unit connects together using a dual flexible single-bolt connection system on each side making it the strongest system in the industry.

Breakwater main docks are typically 14’, 17’, and 20’ wide. Single piece finger piers are typically 5’, 6’, 8’, 10’and 12’ wide and can be up to 60’ long.

MTI Breakwater Series Concrete Docks are built extremely strong and only use high strength concrete (6,000 Psi) with internal HDG steel reinforcing rebar and wire mesh. Stainless steel sockets are cast into the concrete and tied to the internal steel reinforcement, providing high loading capabilities for fender and cleat mounting.

KEY Benefits:

- Remarkable proven strength, durability and stability.

- Twin Keel system for extra draft, increased attenuation performance, and incredible stability.

- Quick and easy installation.

- Designed to last over half a century with very little maintenance.

- Standard 24” freeboard.

- Internal utility routing via sleeves and or single or dual top-access utility troughs.

- Your choice of composite, rubber, vinyl or wood fenders.

- Proven flexible connections designed for rough water conditions.

- No hi-maintenance cables, timber, walers or thru-rods.

- Top-access, internal connection boxes for chain or flexible anchoring systems.

- Internal or external pile guides in either HDG steel or 316L stainless steel.

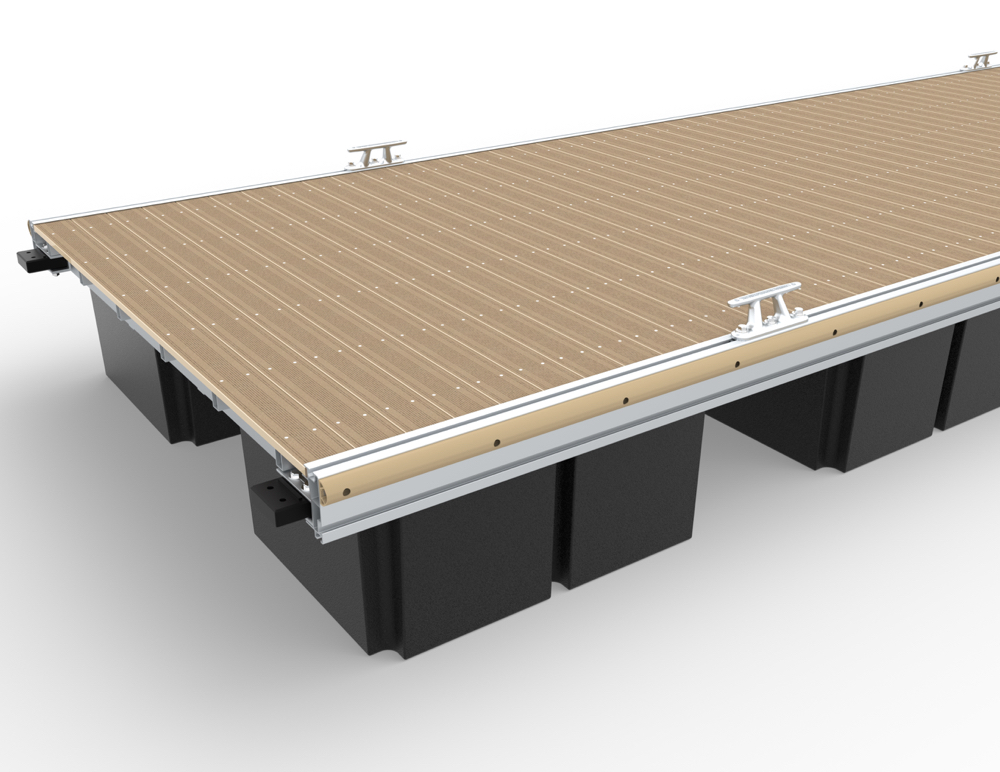

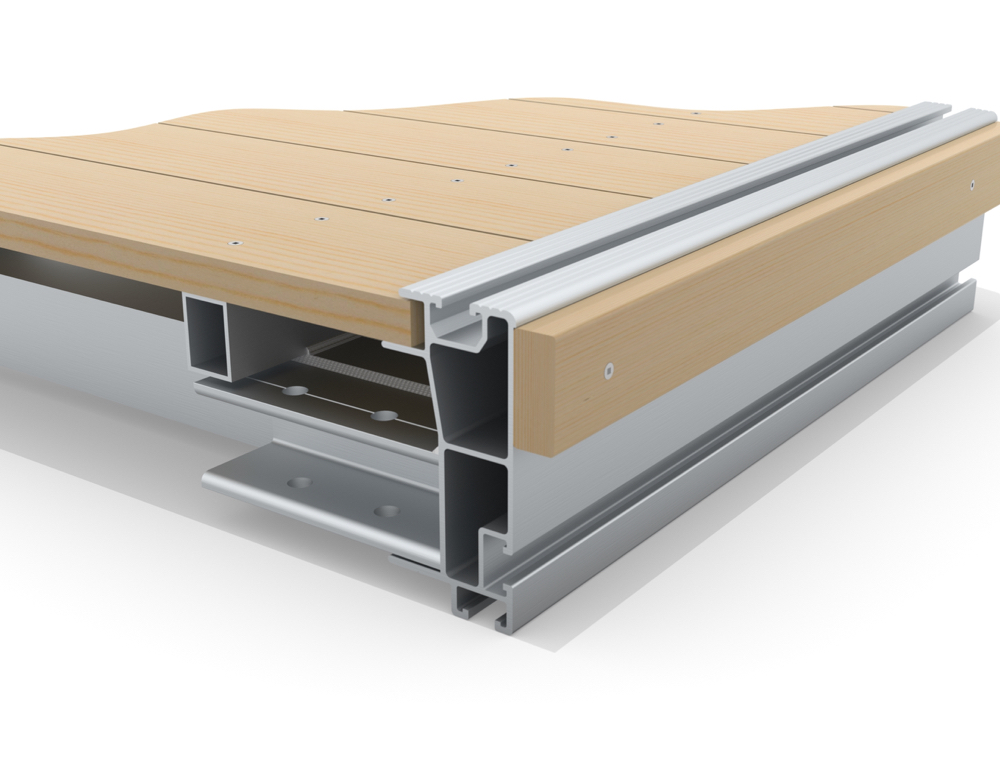

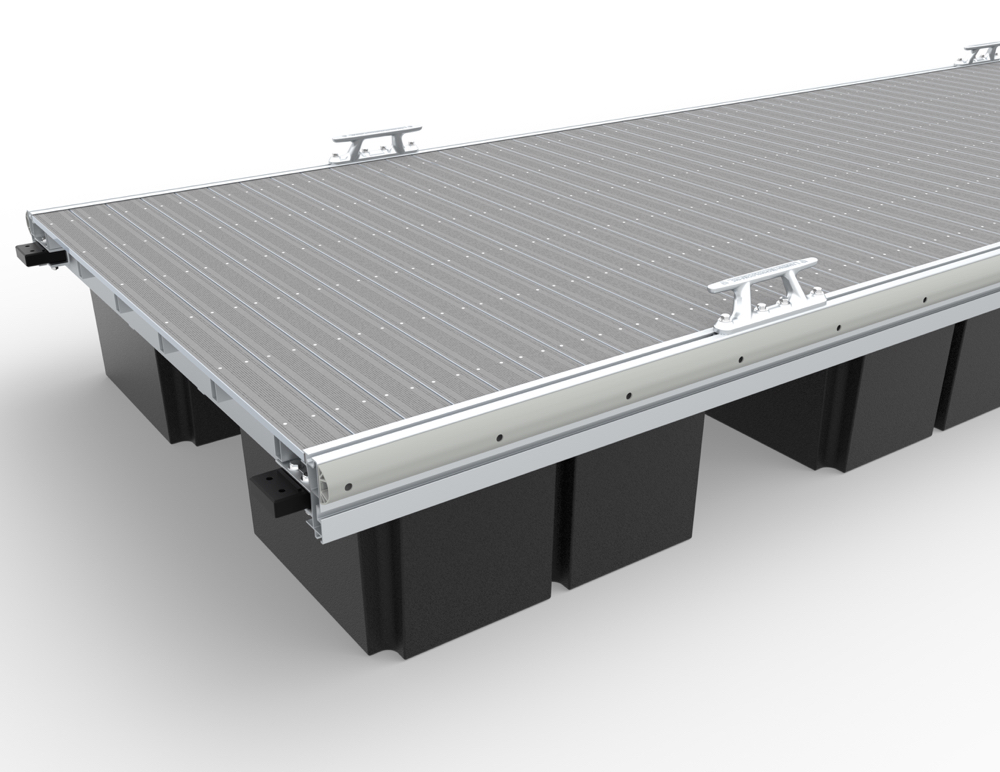

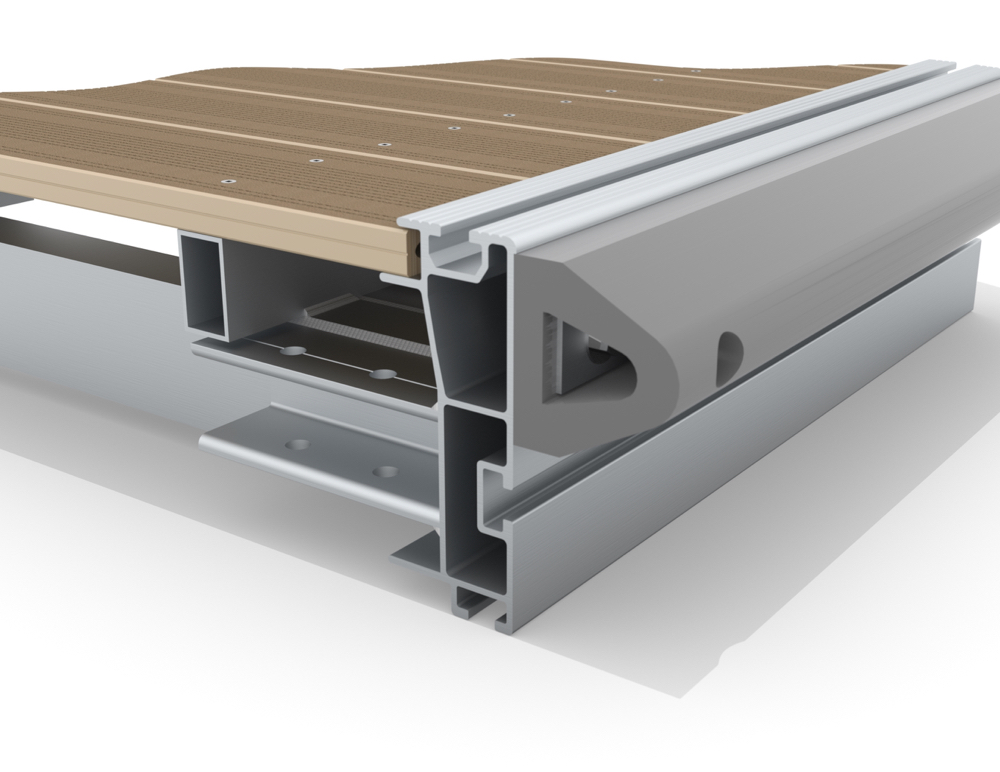

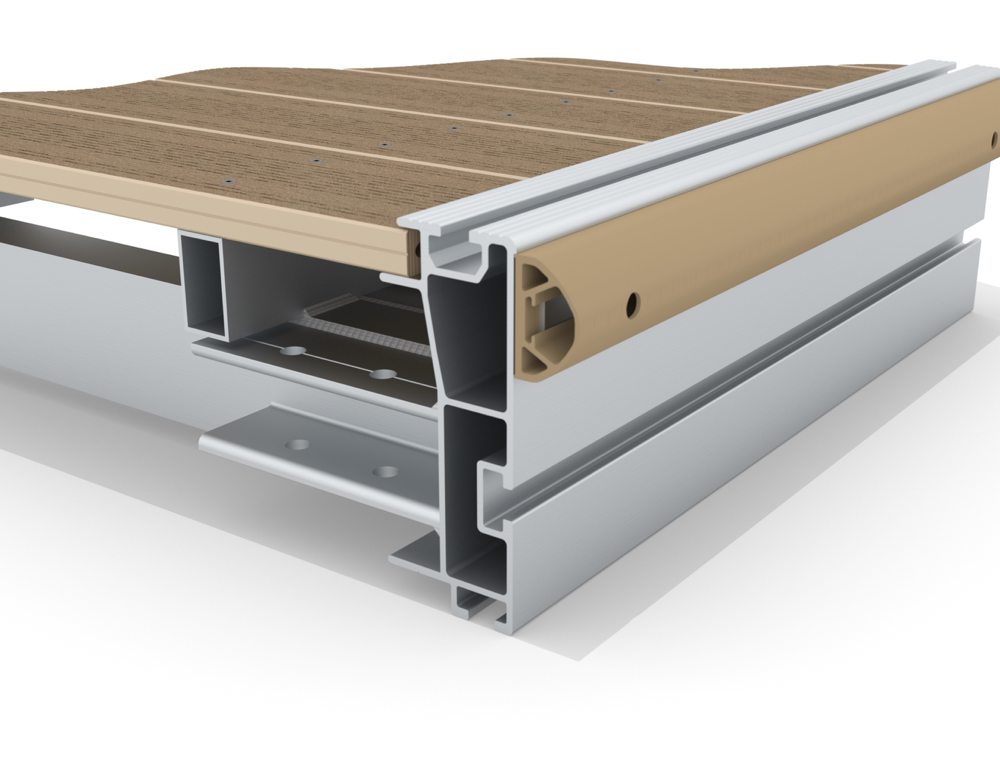

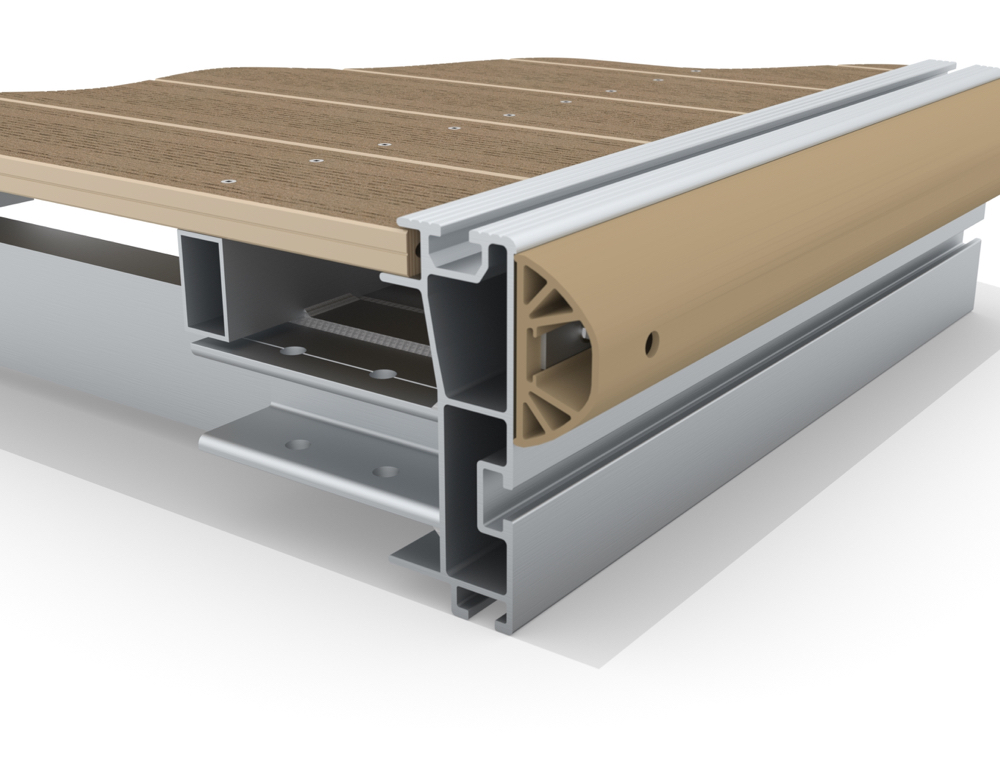

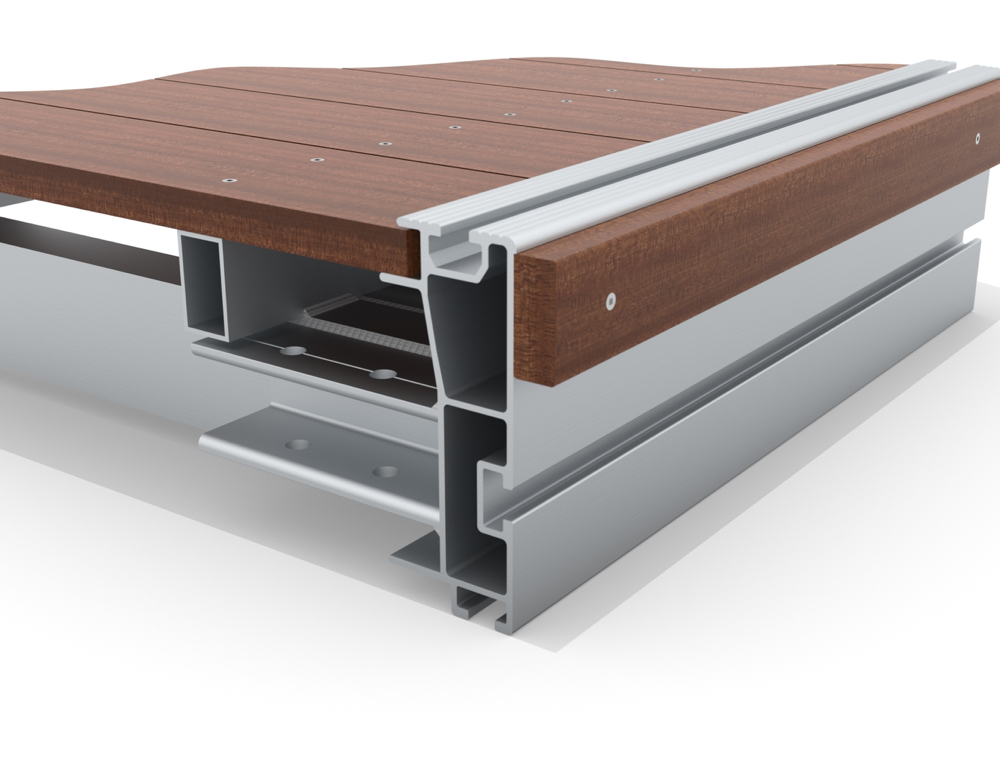

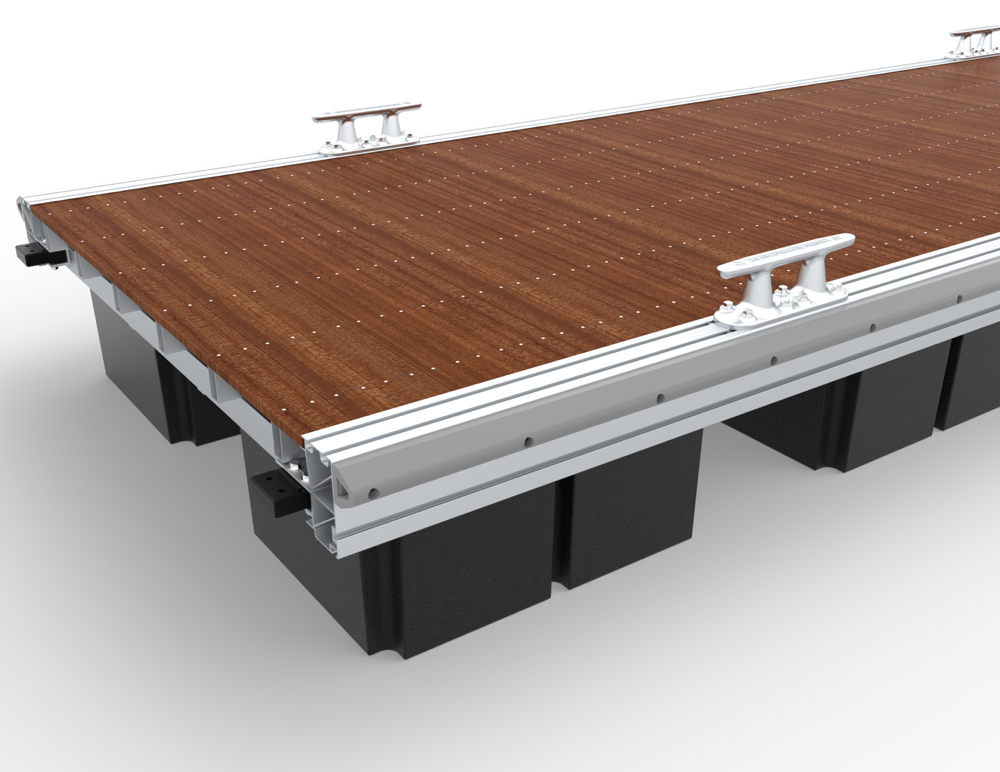

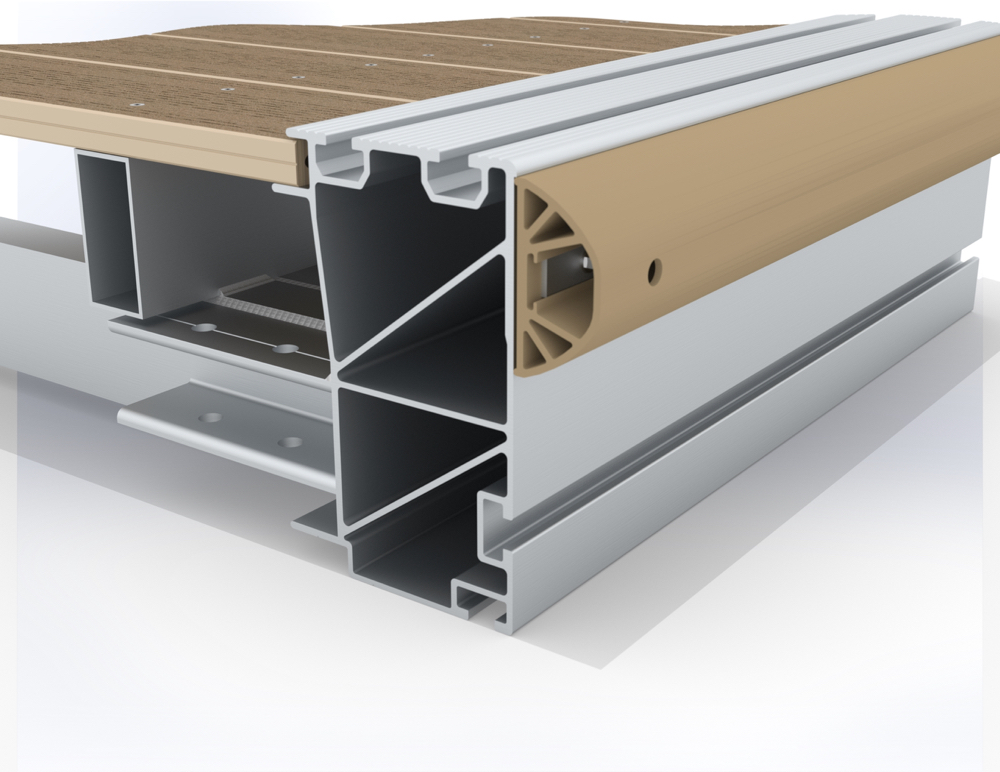

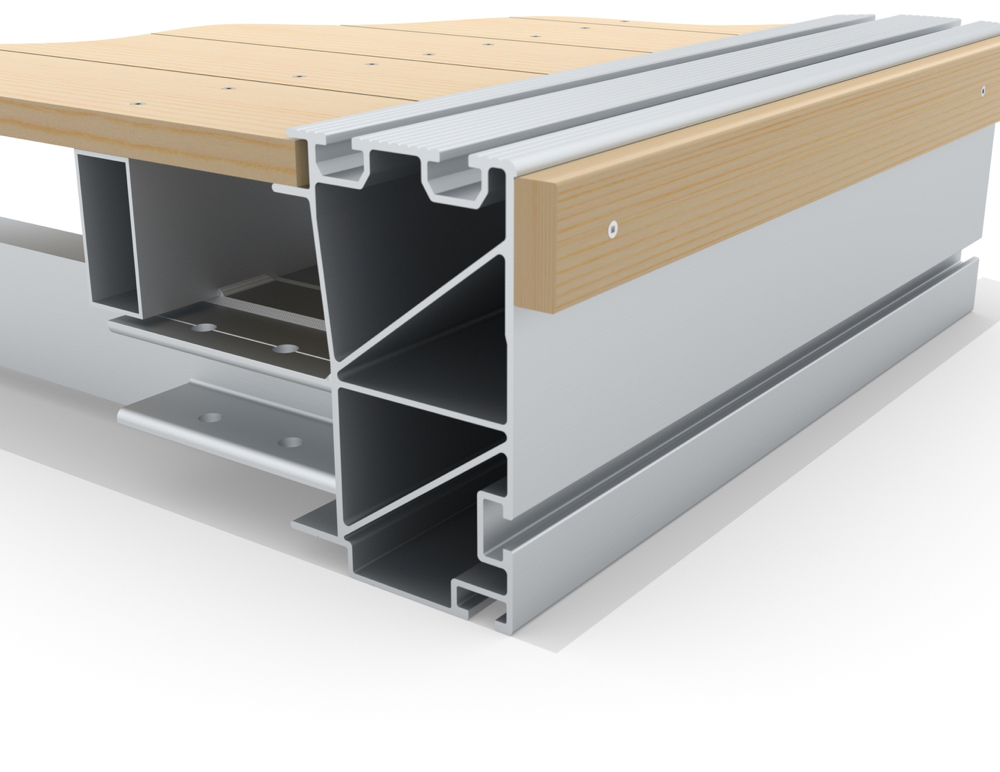

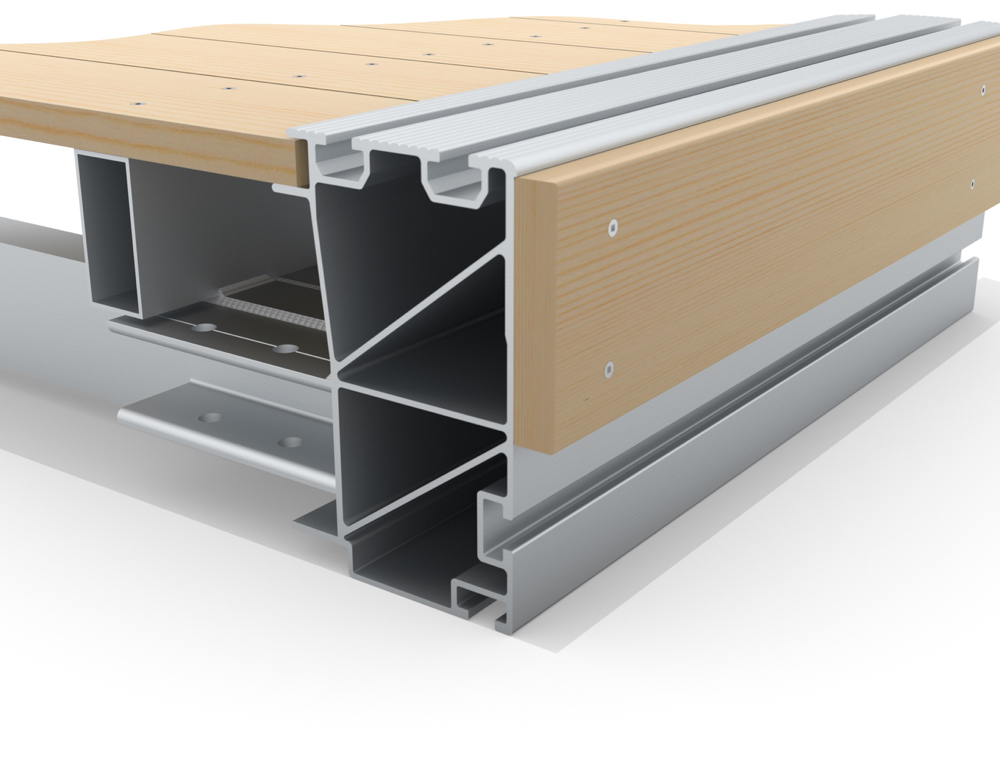

MTI-S190 SERIES ALUMINUM DOCKS

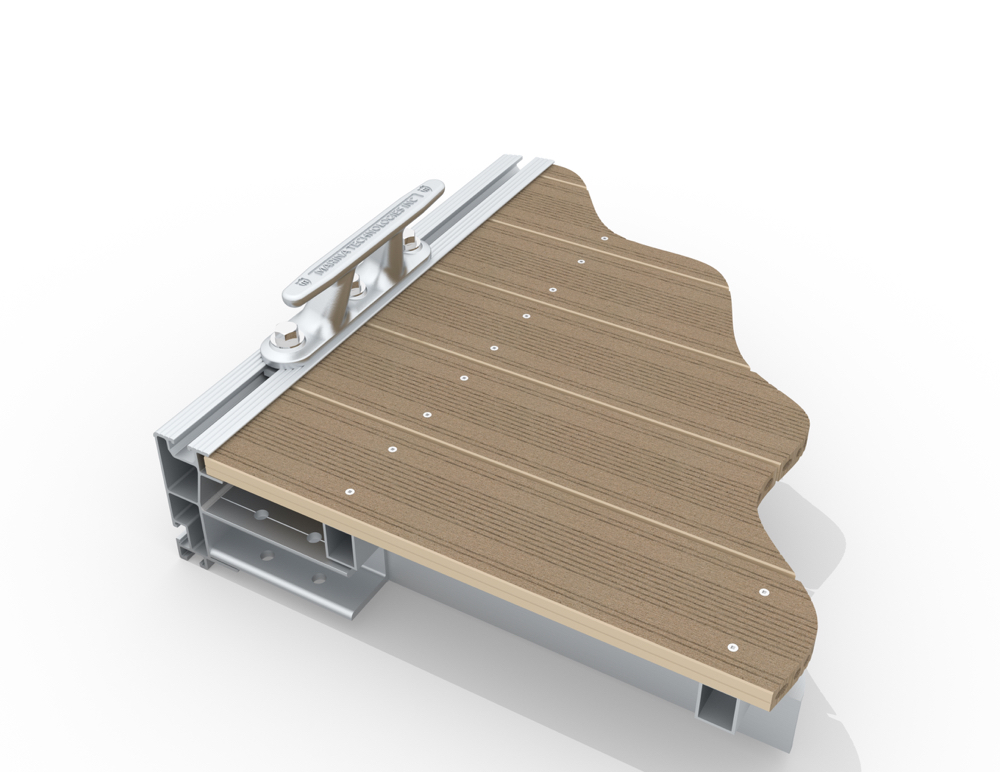

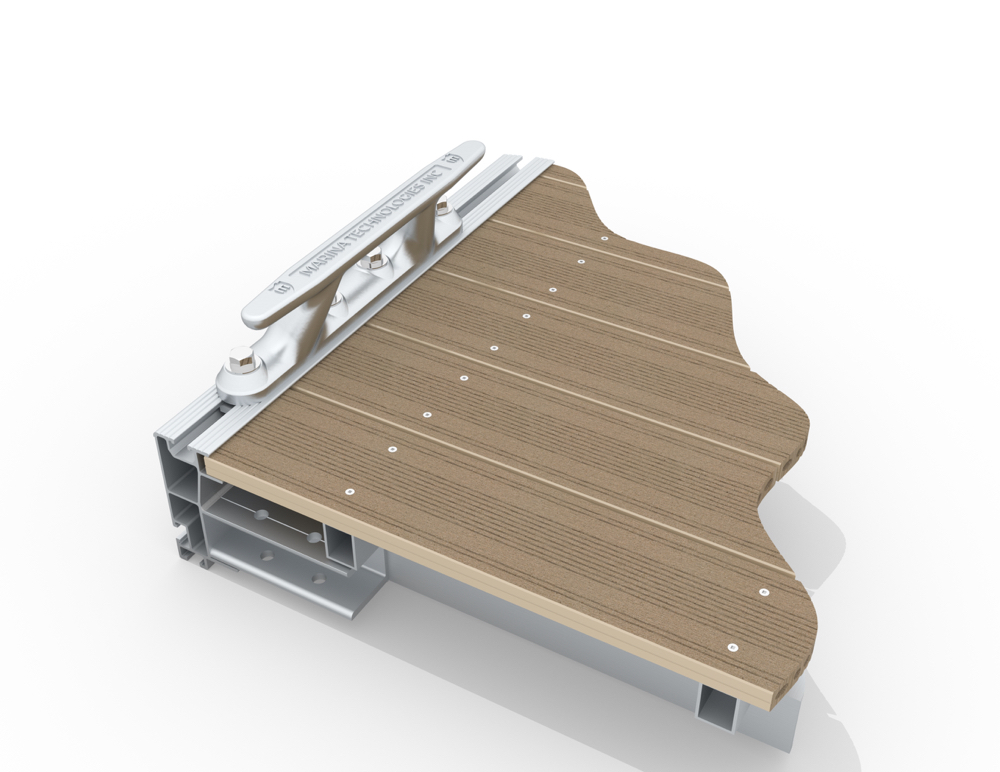

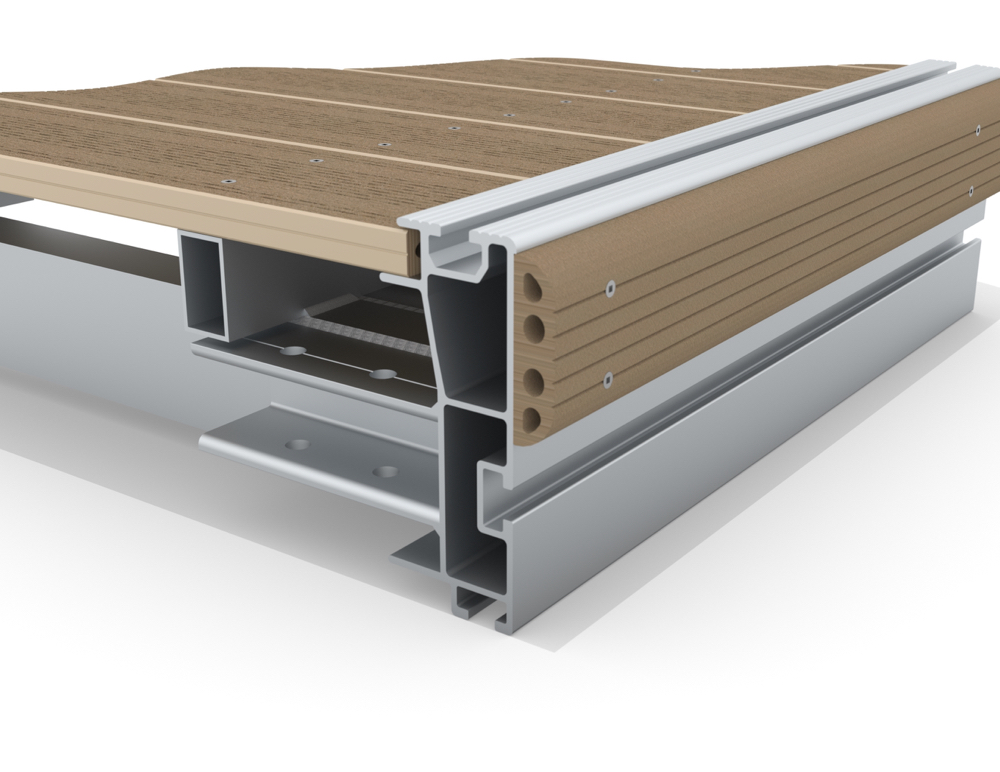

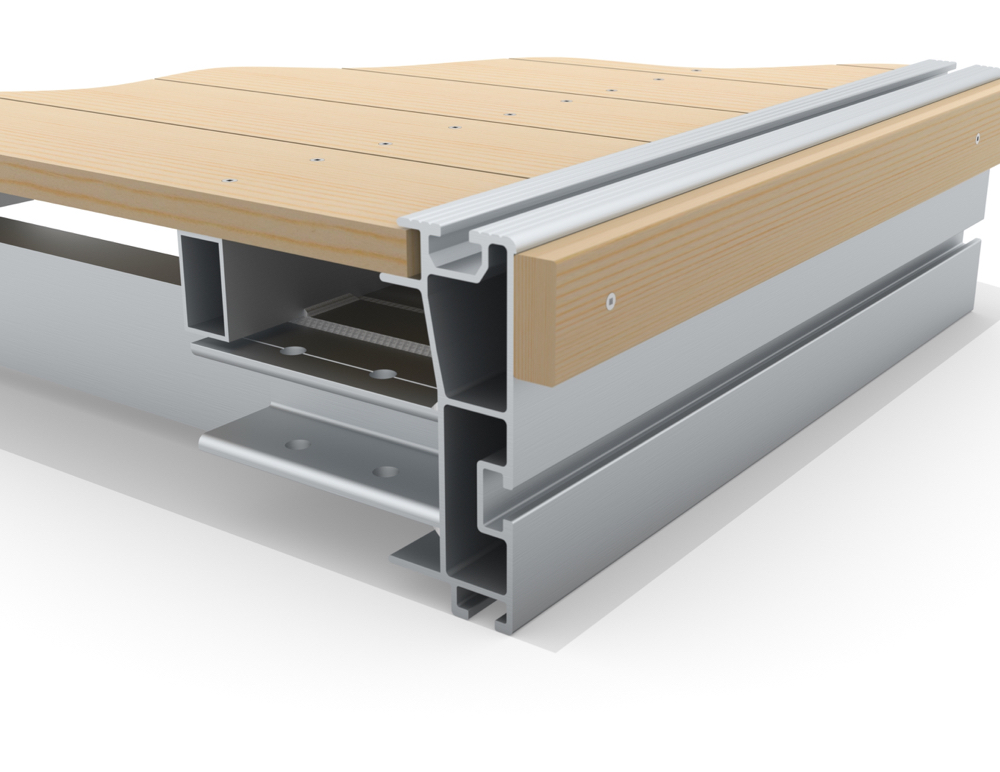

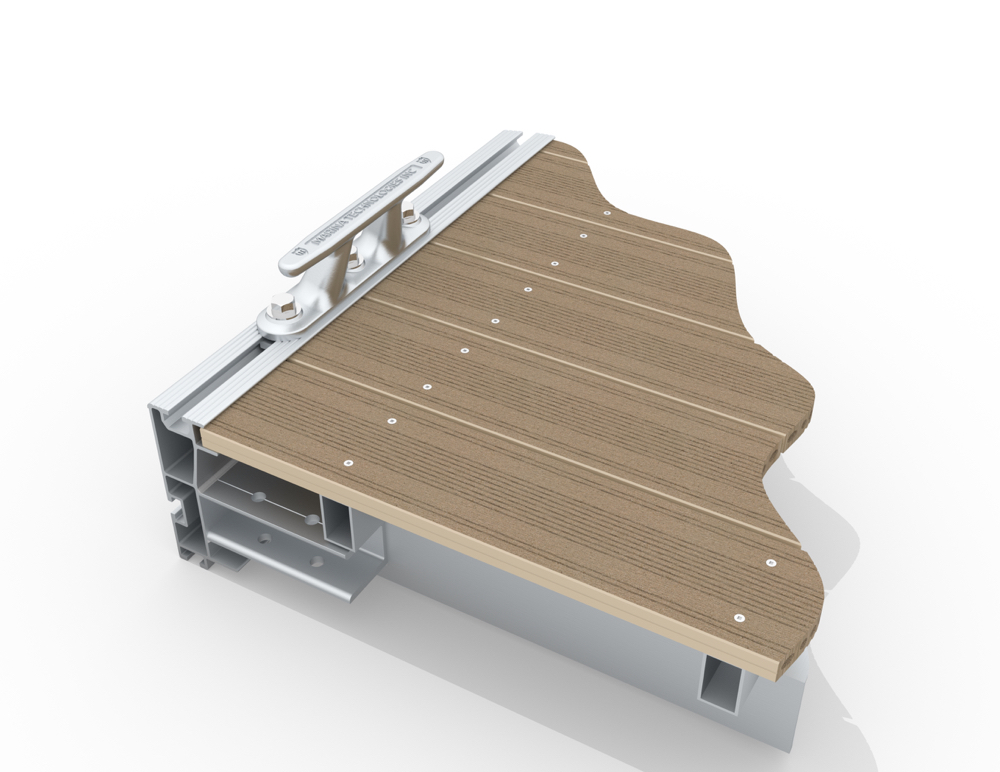

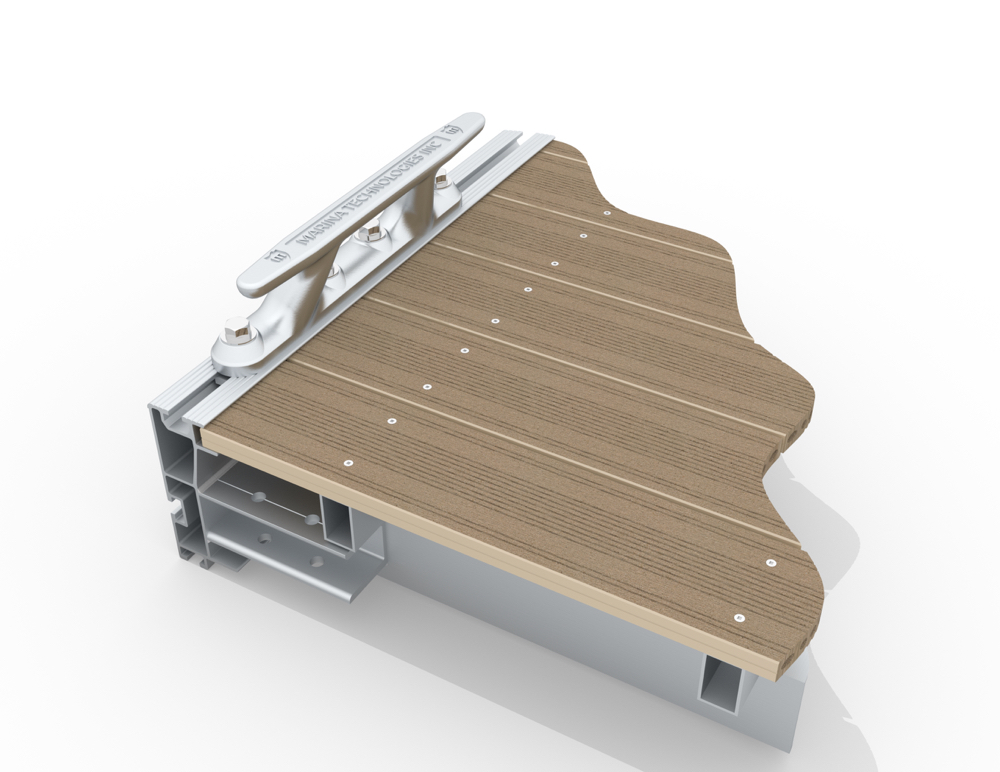

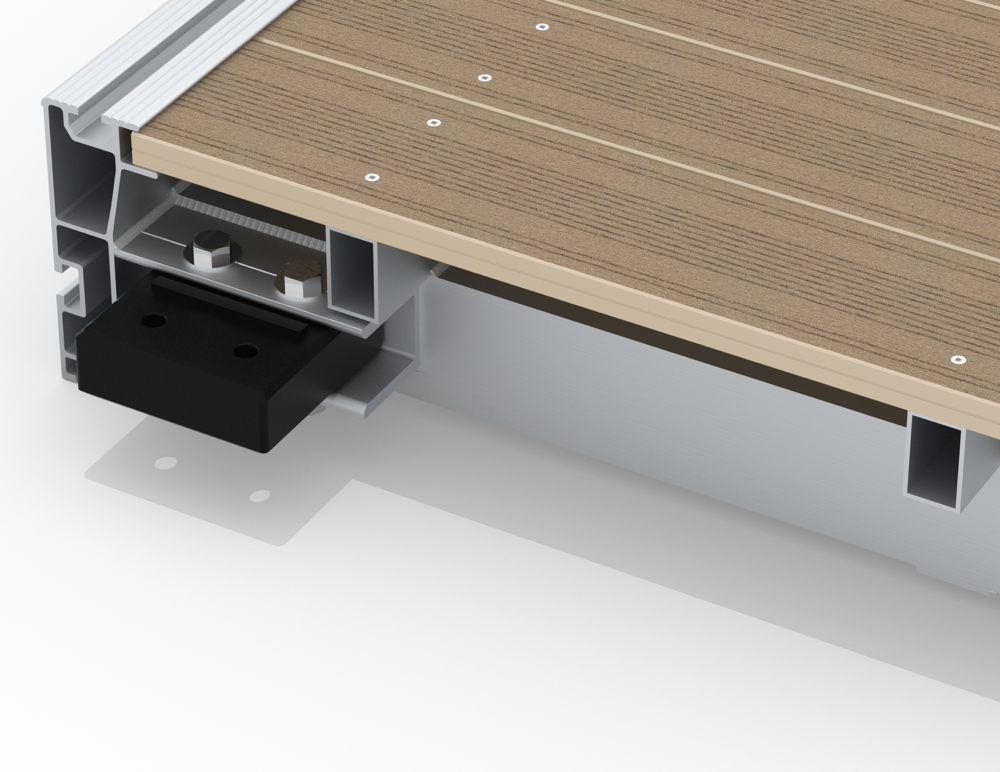

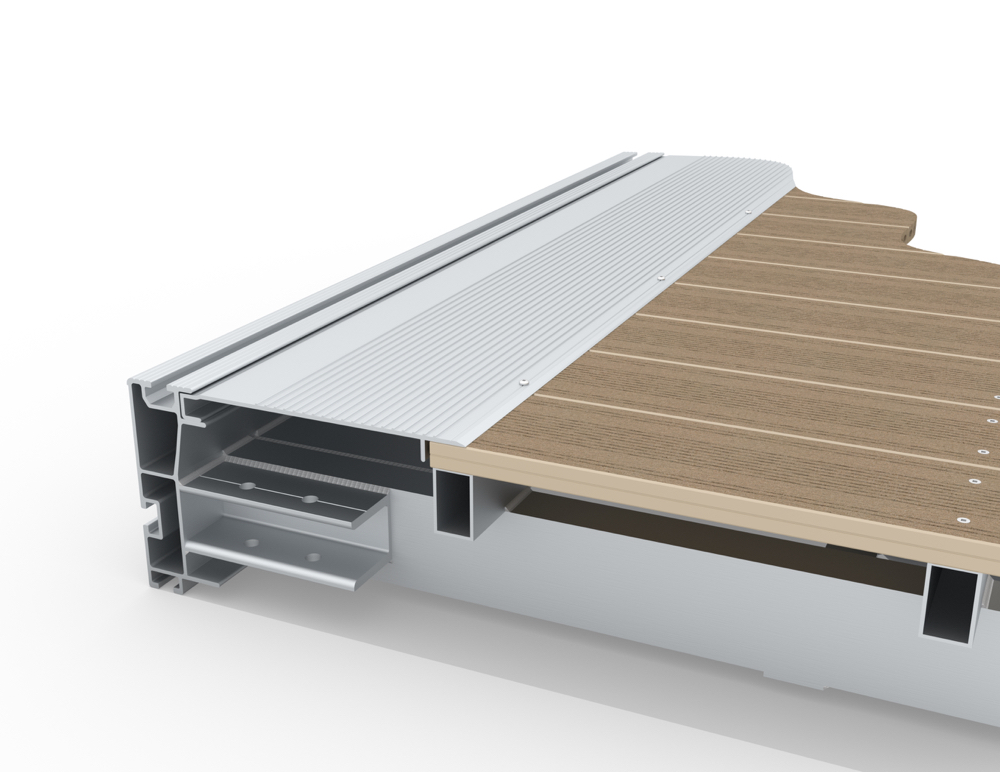

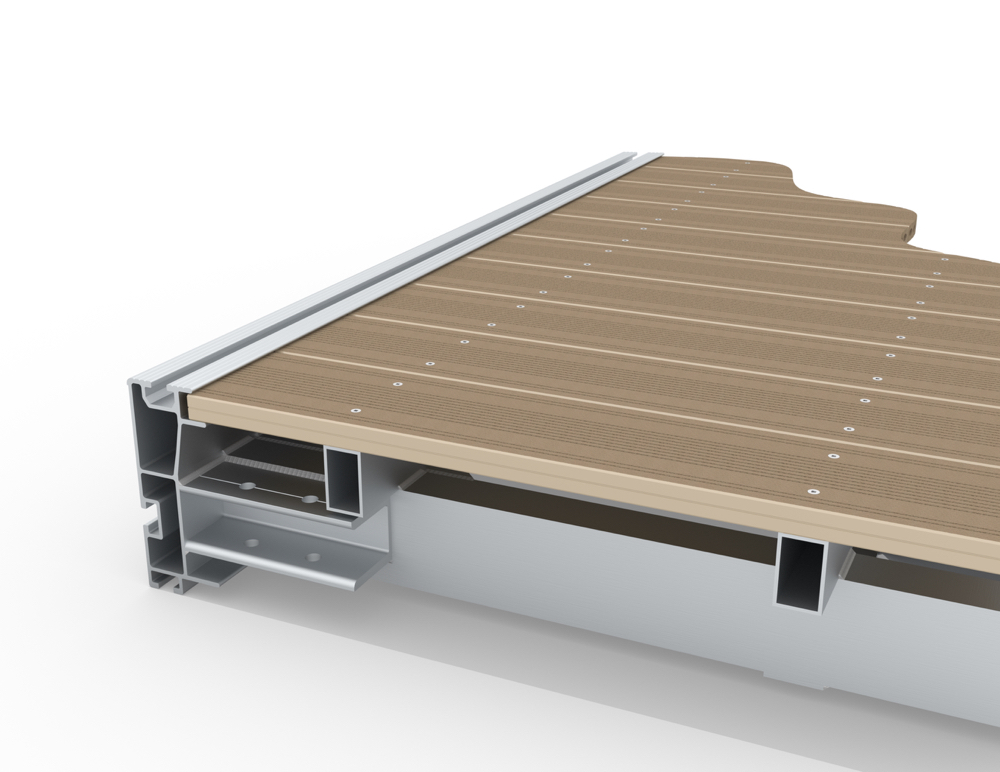

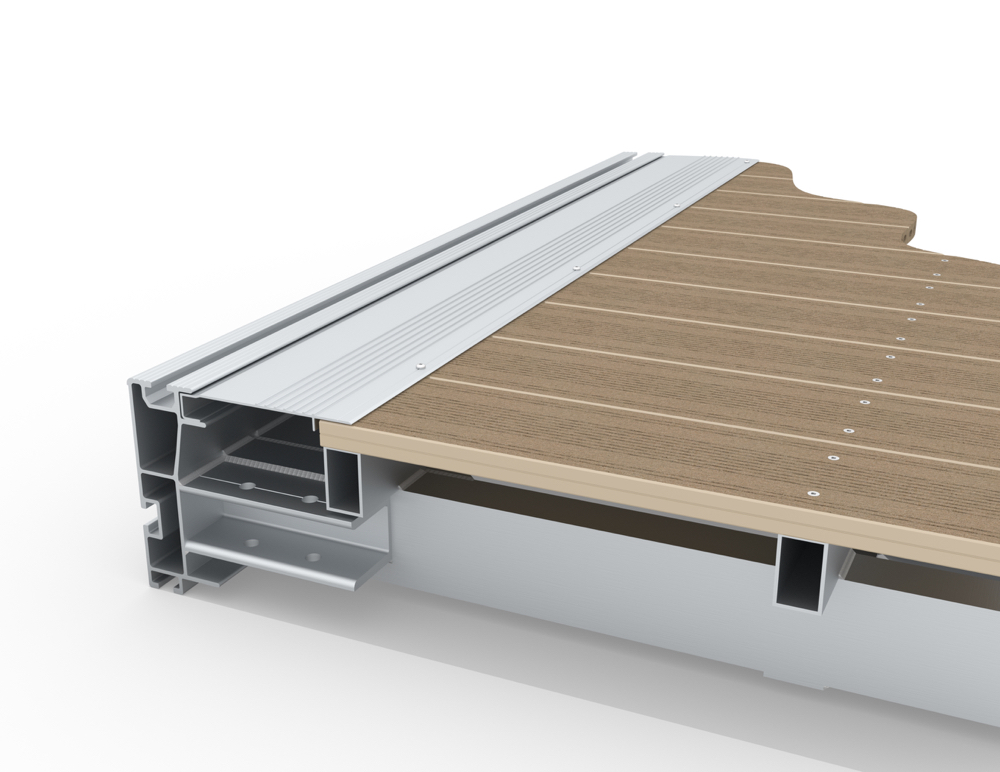

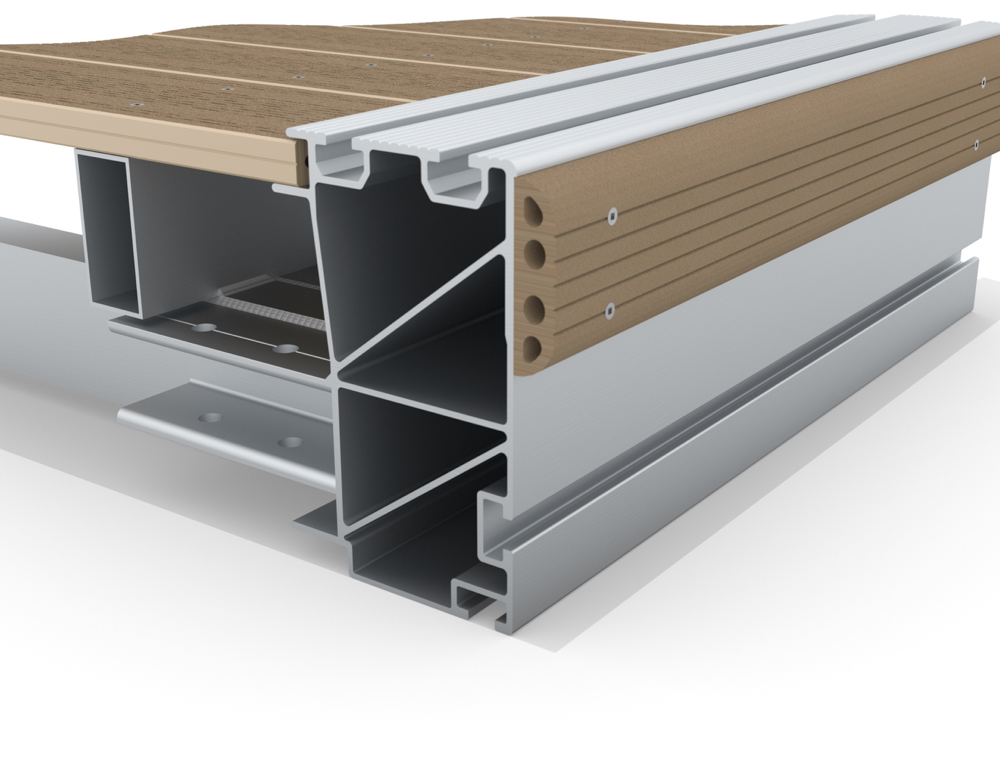

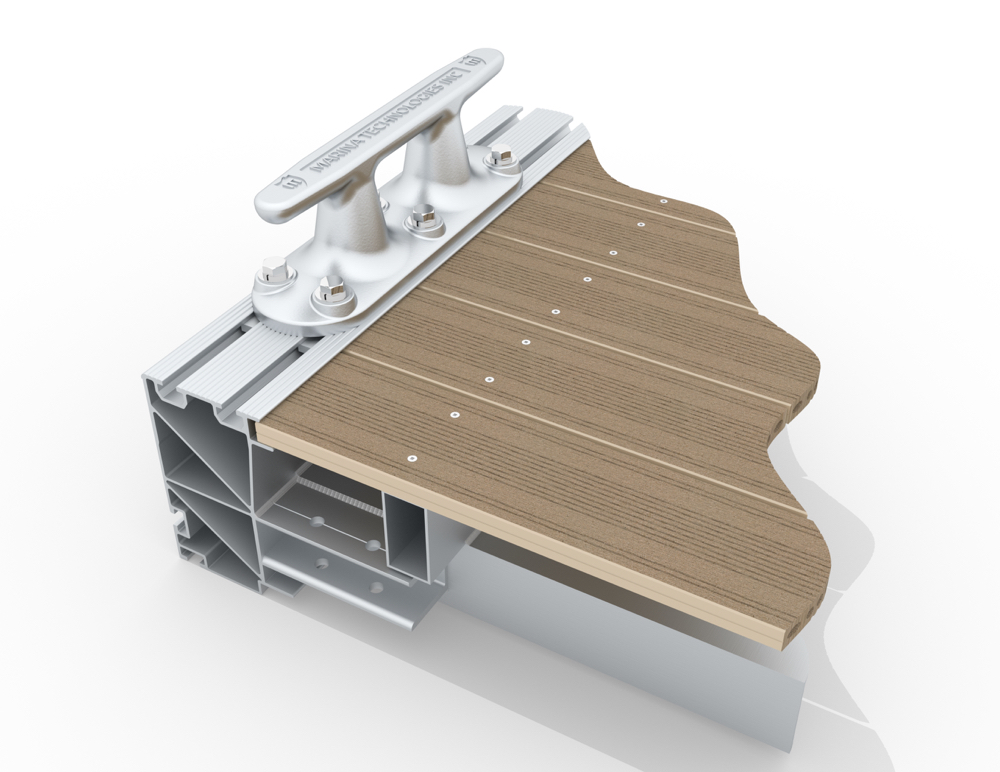

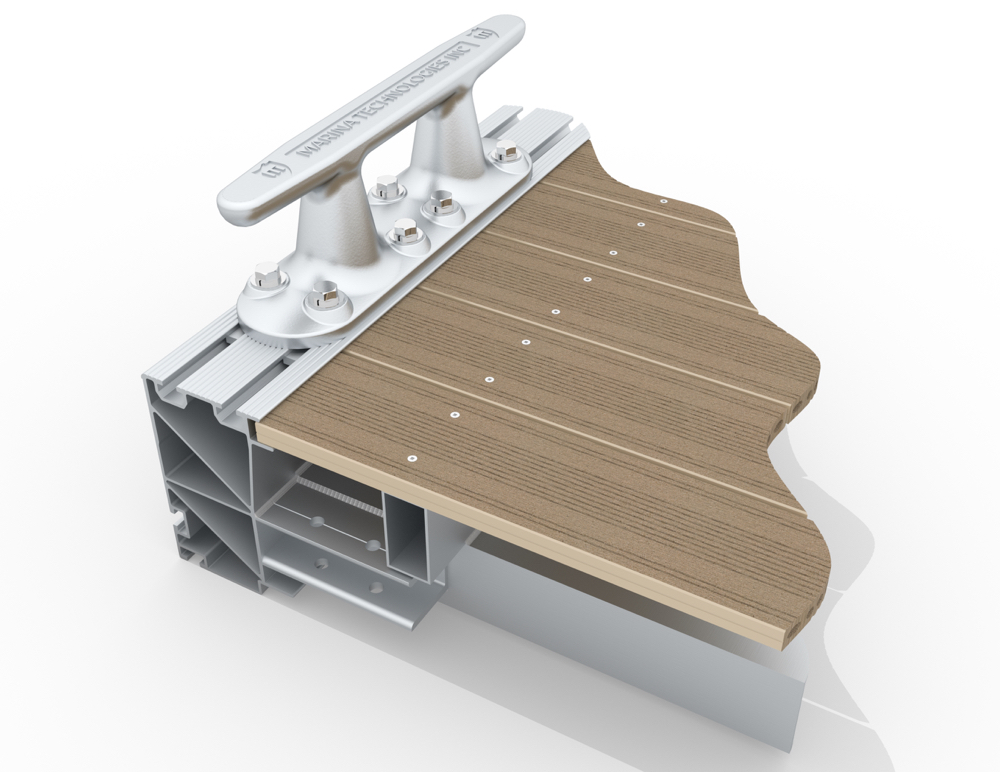

The MTI-S190 Series Aluminum Docks are constructed using Marine-Grade 6061-T6 Aluminum alloy and are designed and engineered to be strong, maintenance free and elegant. The MTI-S190 Series is an advanced and versatile aluminum system that exceeds your expectations. One of the most notable and useful features is the built-in top, bottom and lateral track system allowing for quick installation and repositioning of finger piers and cleats.

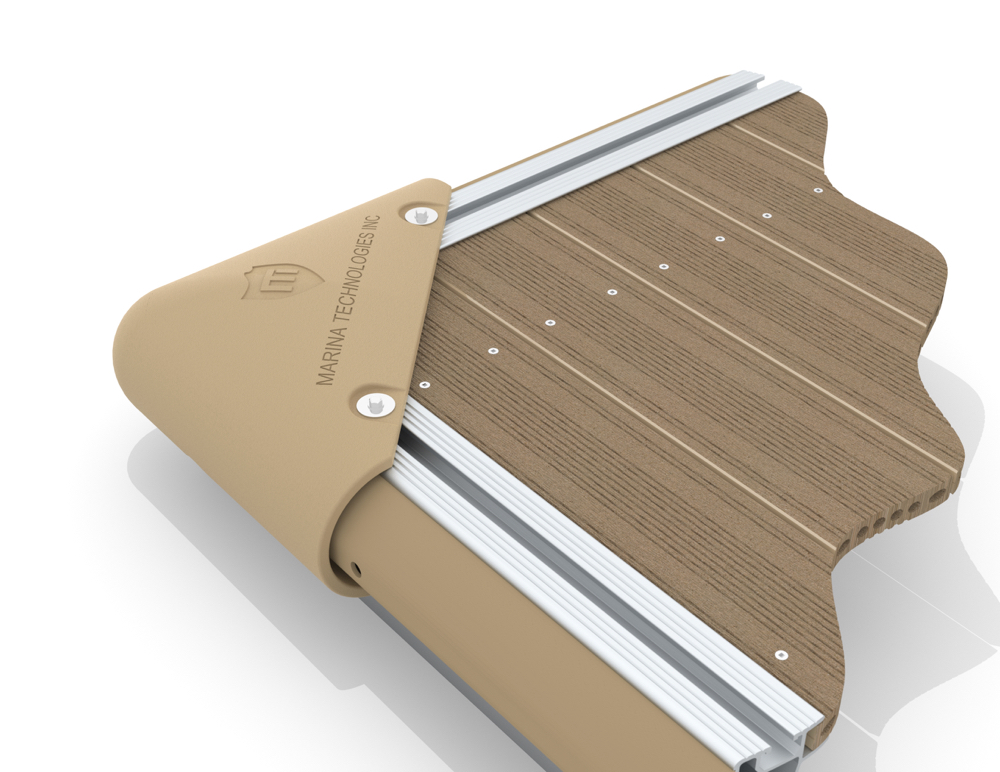

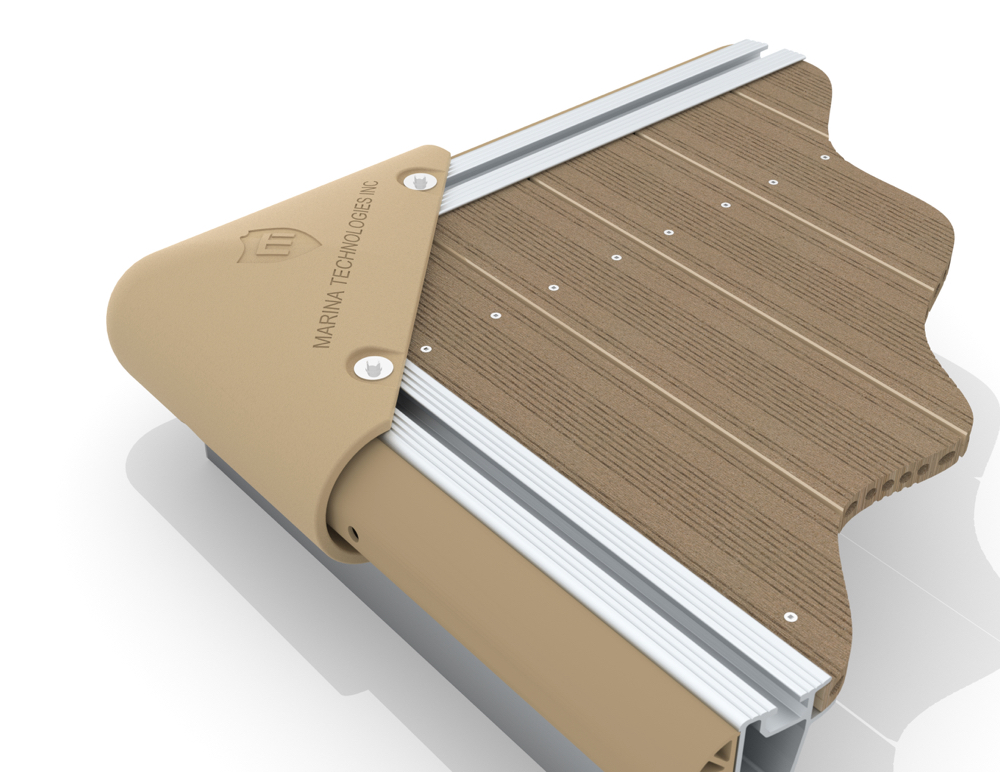

The MTI-S190 dock sections are typically 40’ long and quickly connect together using strong noise-free high density rubber connectors with stainless steel hardware. The MTI-S190 main docks are typically 4’, 6’, 8’ 10’ and 12’ wide. Single piece finger piers are typically 3’, 4’, 5’, 6,’ and 8’ wide and come rectangular or tapered.

The MTI-S190 Series Aluminum Docks also offer an optional floatation system using HI-STABILITY CONCRETE floats which greatly increases the dock mass, stability and loading capacity. This unique system combines the elegance of our aluminum series with the proven strength and stability of our concrete products. Each HI-STABILITY CONCRETE float weighs approximately 2,500 - 4,000 lbs. and offers extra resistance to tropical storms/hurricanes, ice, and floating debris. The stability is incredible and approaches the feel of an all concrete dock.

KEY Benefits:

- Proven strength, durability and stability.

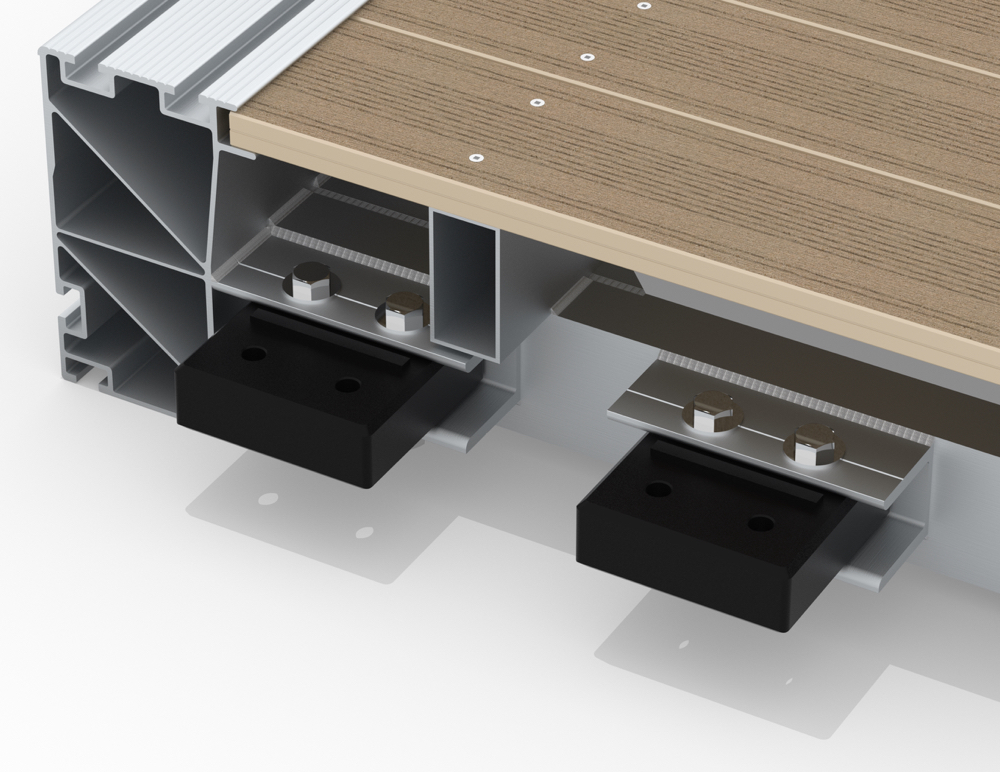

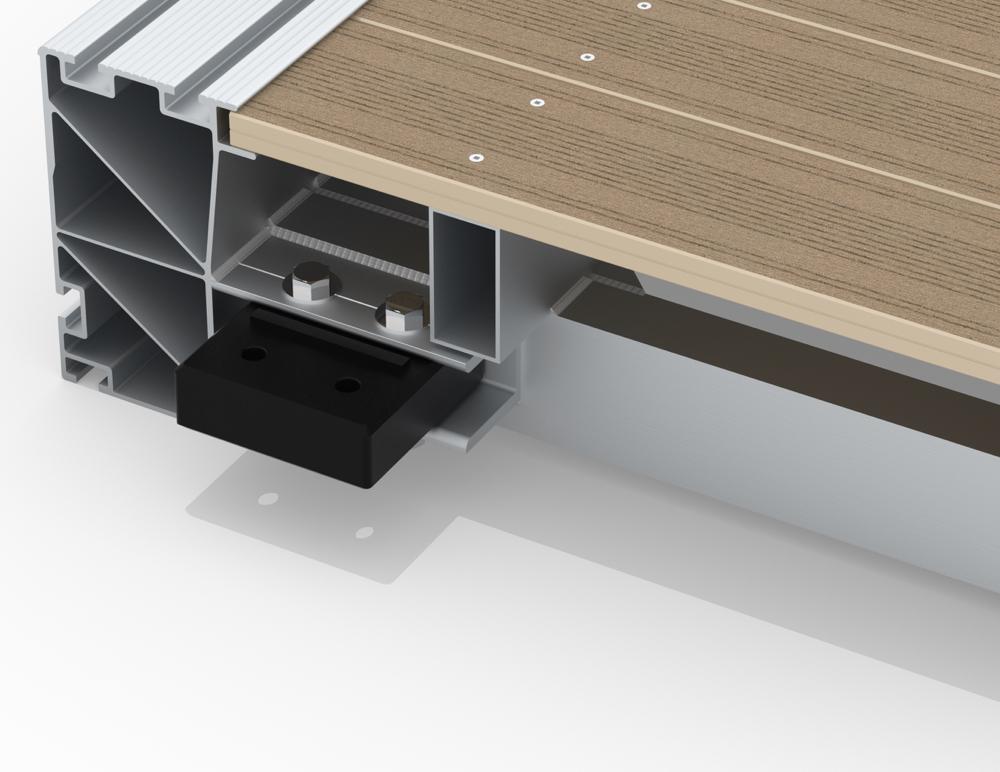

- Polyethylene floats or unique HI-STABILITY CONCRETE floats.

- Noise-free, strong, and flexible rubber connectors allow the dock to perform in rough water conditions

- Built in growth potential - track System on all mains and fingers for quick assembly and reconfiguration - cleats, fingers and pile guides are easily repositioned also.

- Unique inner stainless-steel back plate within the track system for extra strong cleat connections.

- Quick and easy installation.

- 35 year design life with minimal maintenance.

- 18” standard freeboard.

- Internal utility routing and/or single or dual top-access utility troughs.

- Several fender options to choose from such as hardwood, composite, PVC, and rubber fenders with matching color corner bumpers.

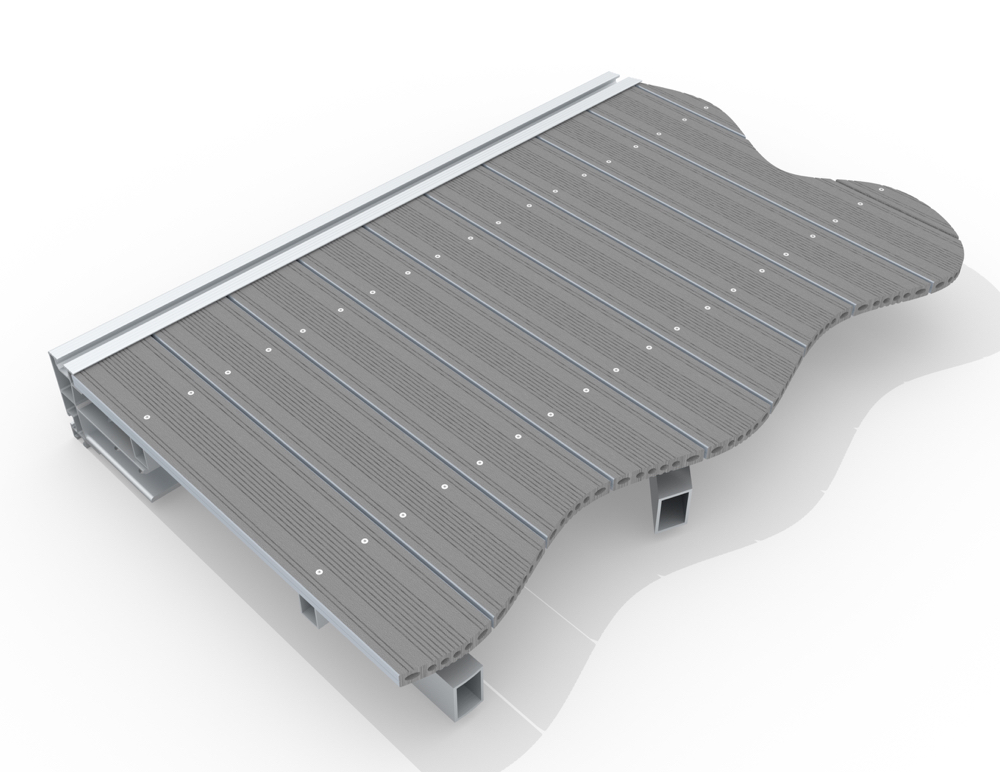

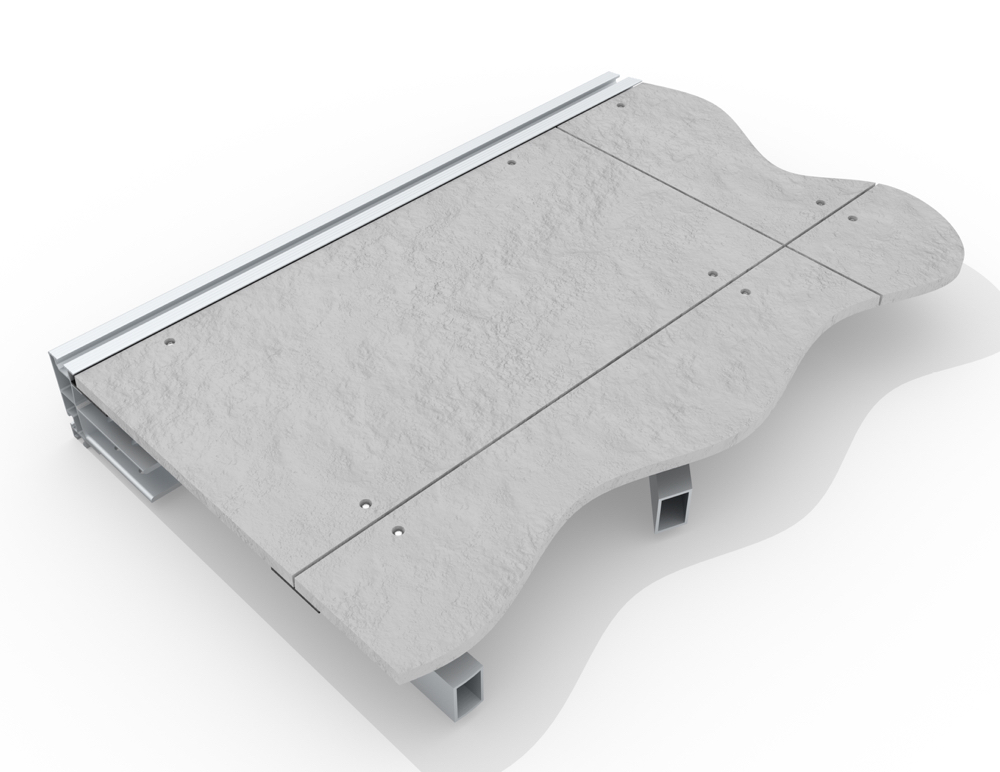

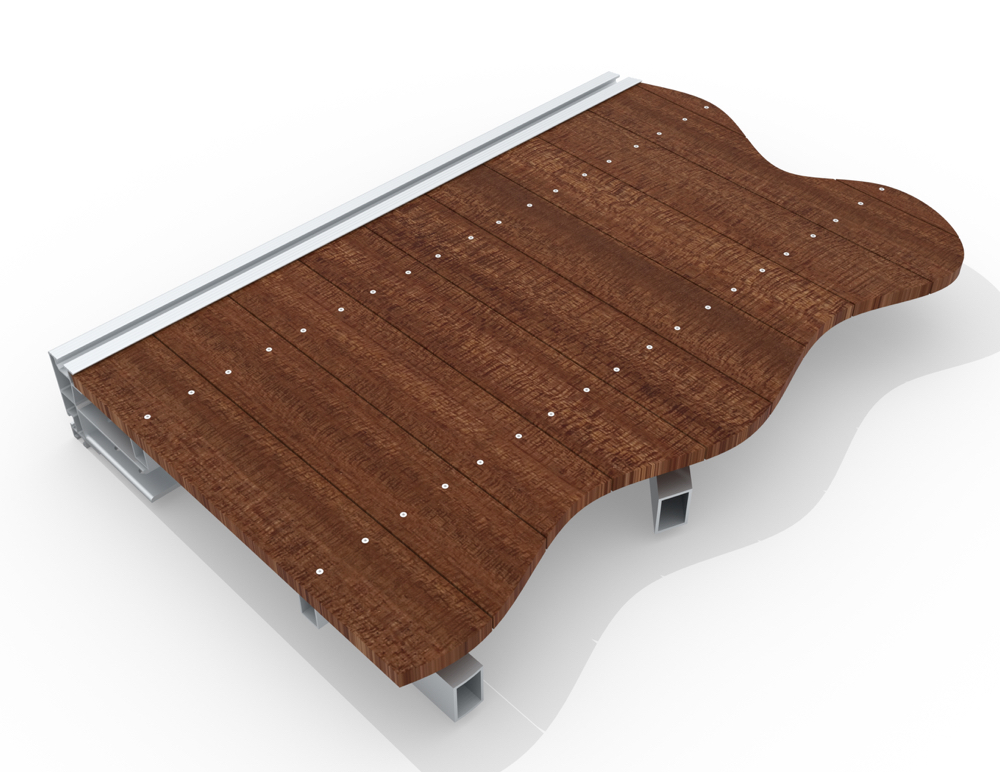

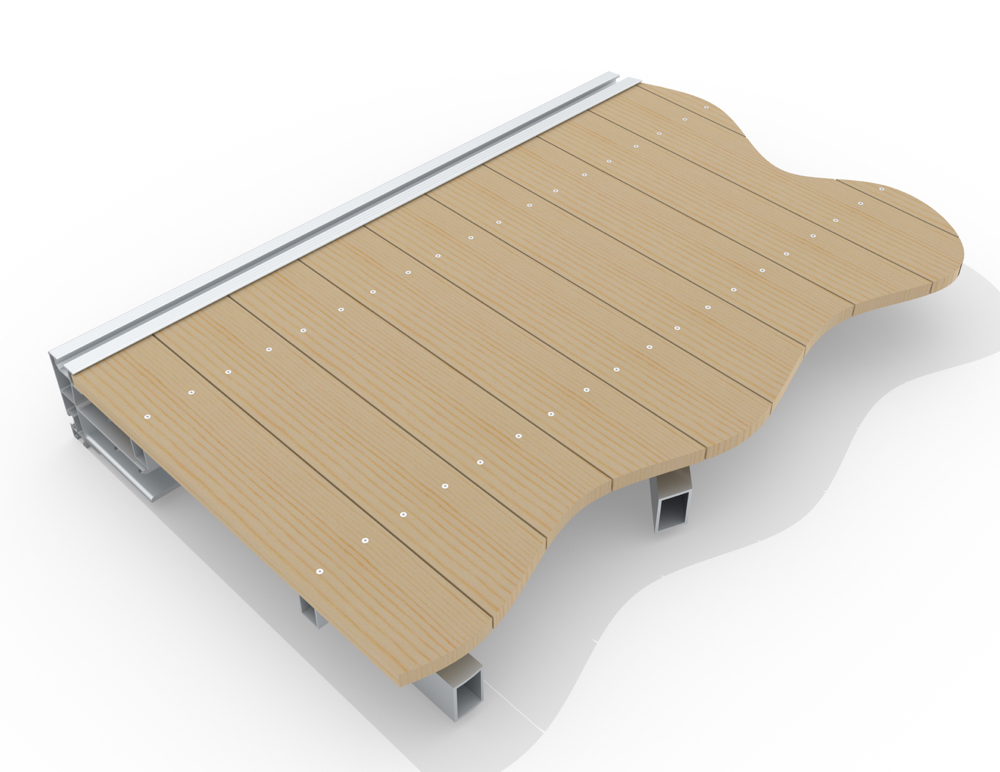

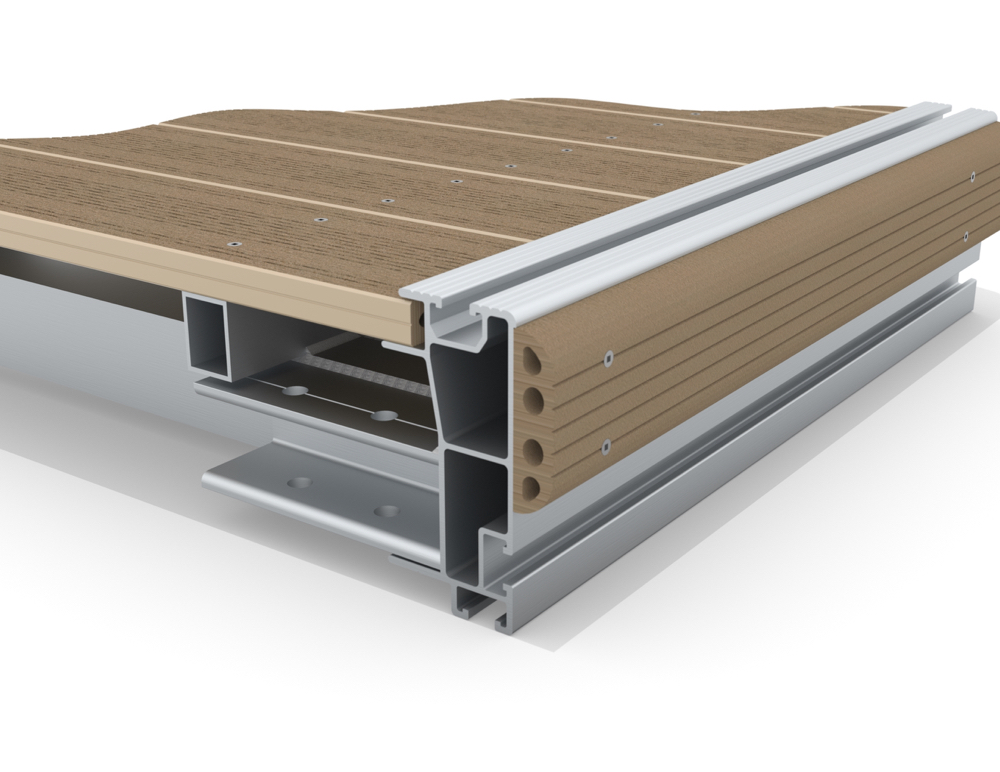

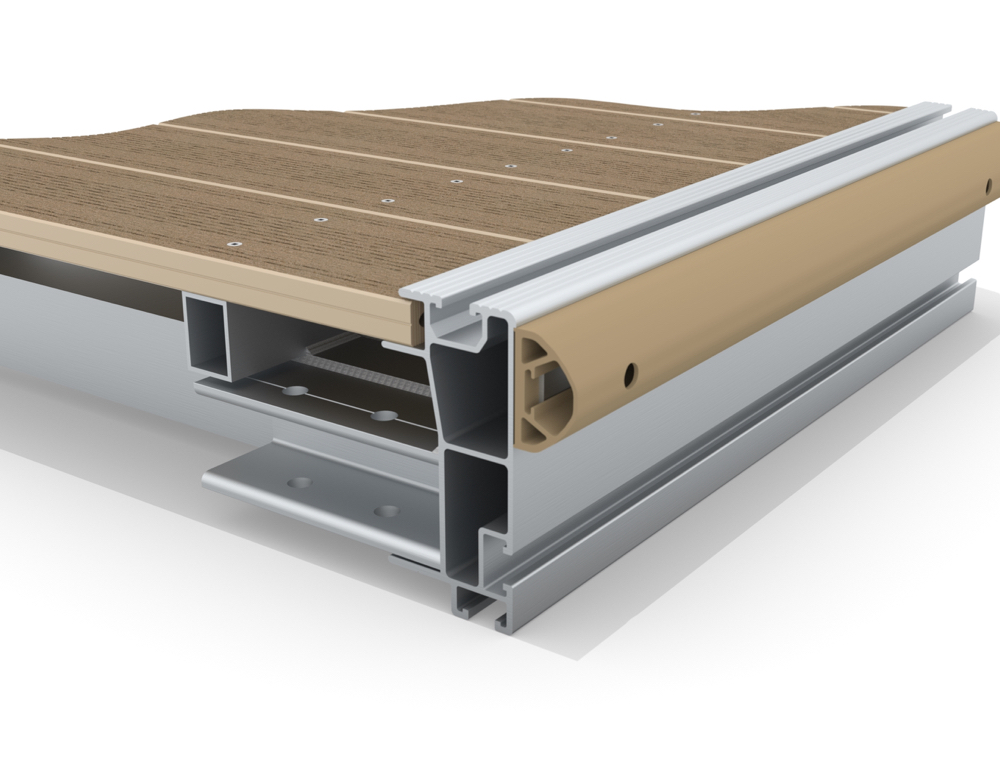

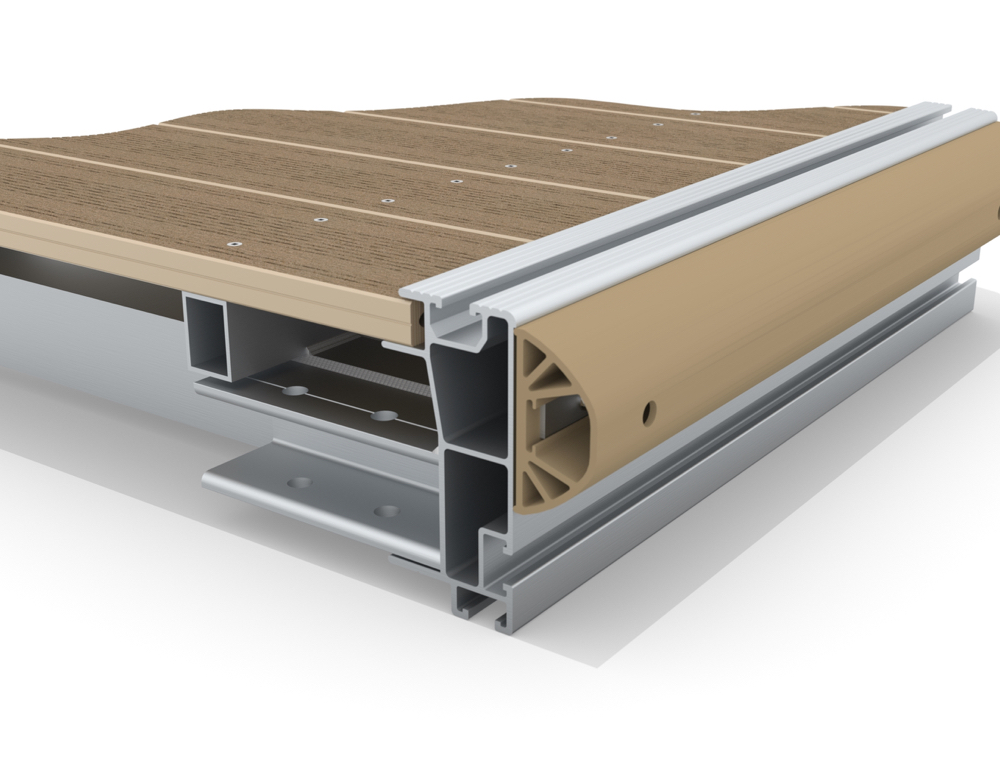

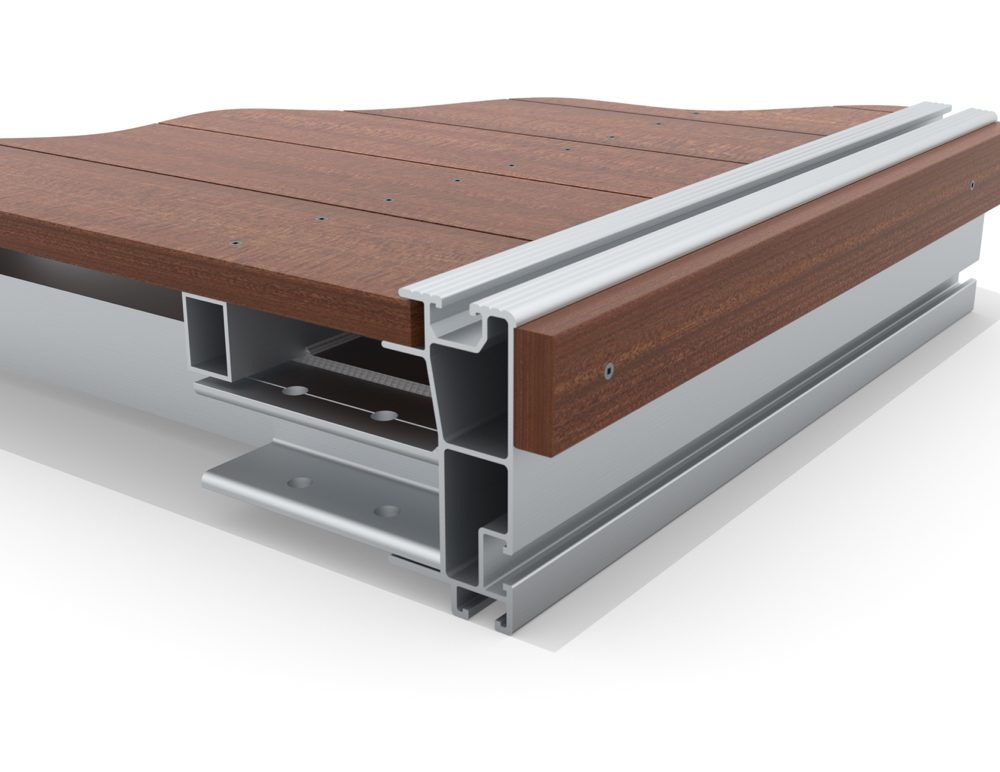

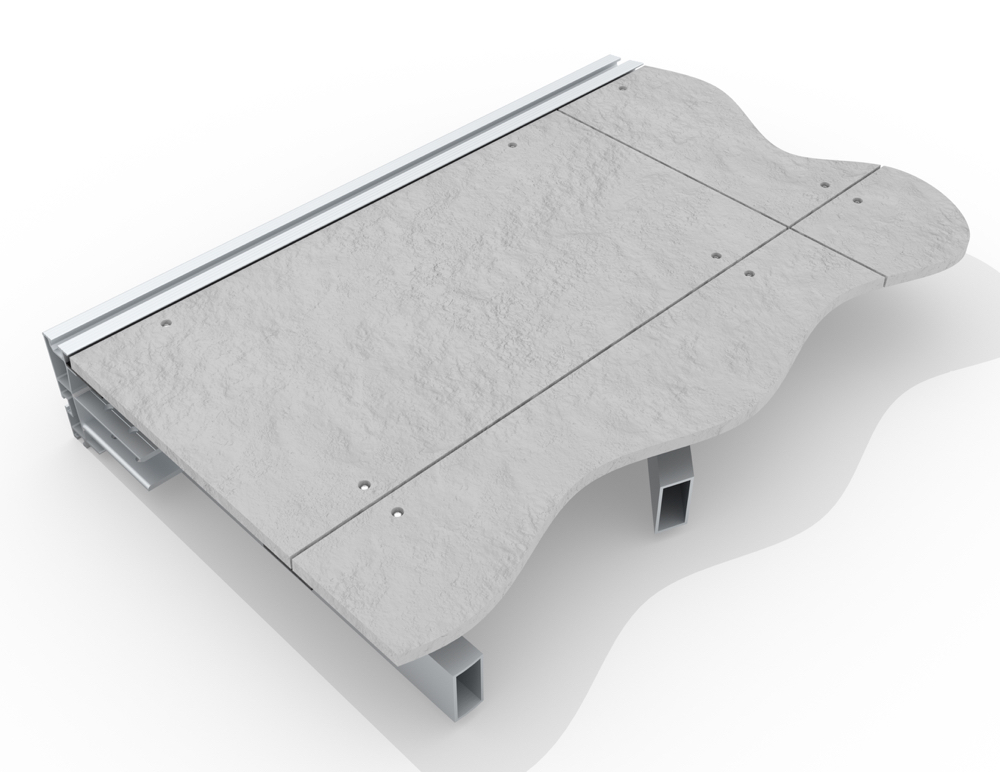

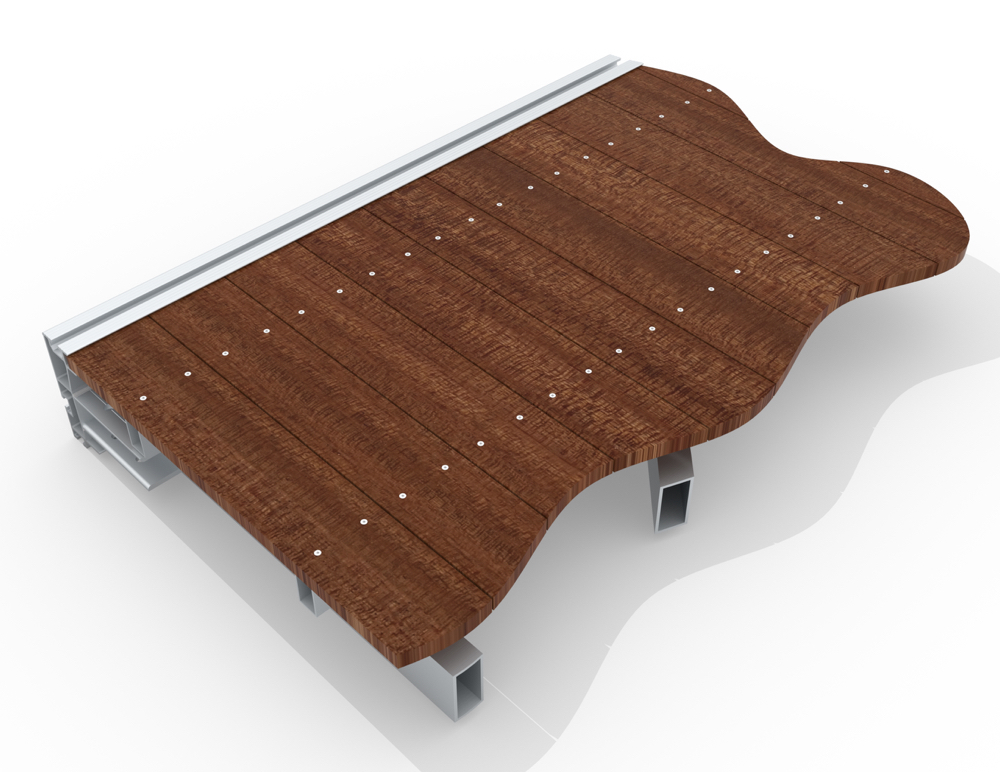

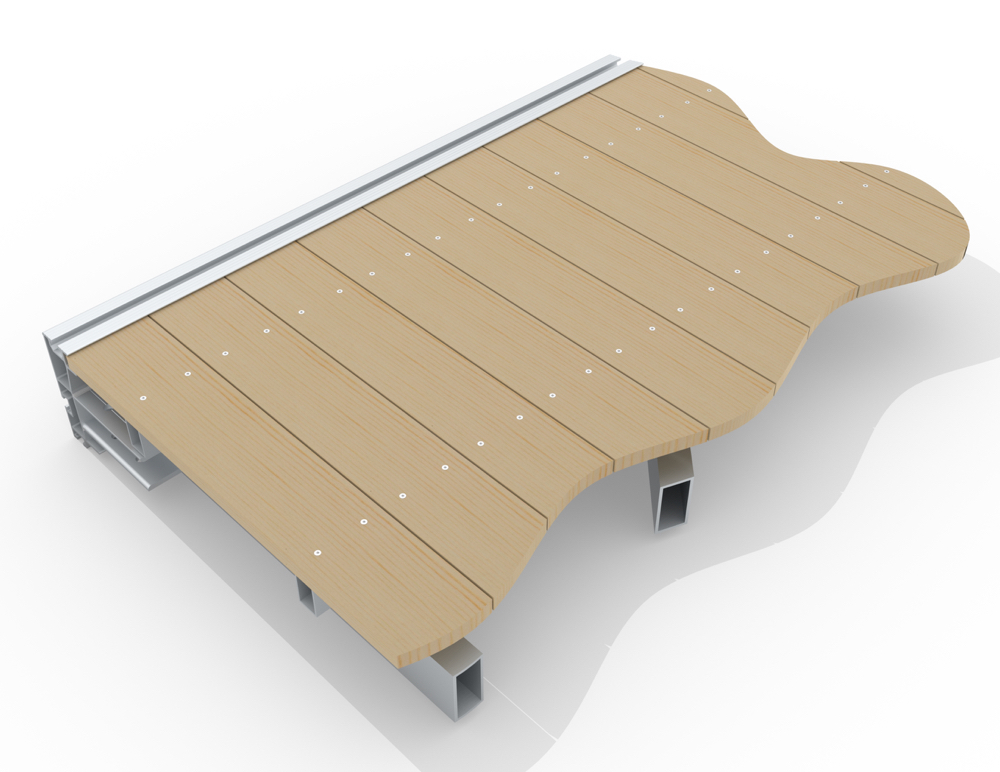

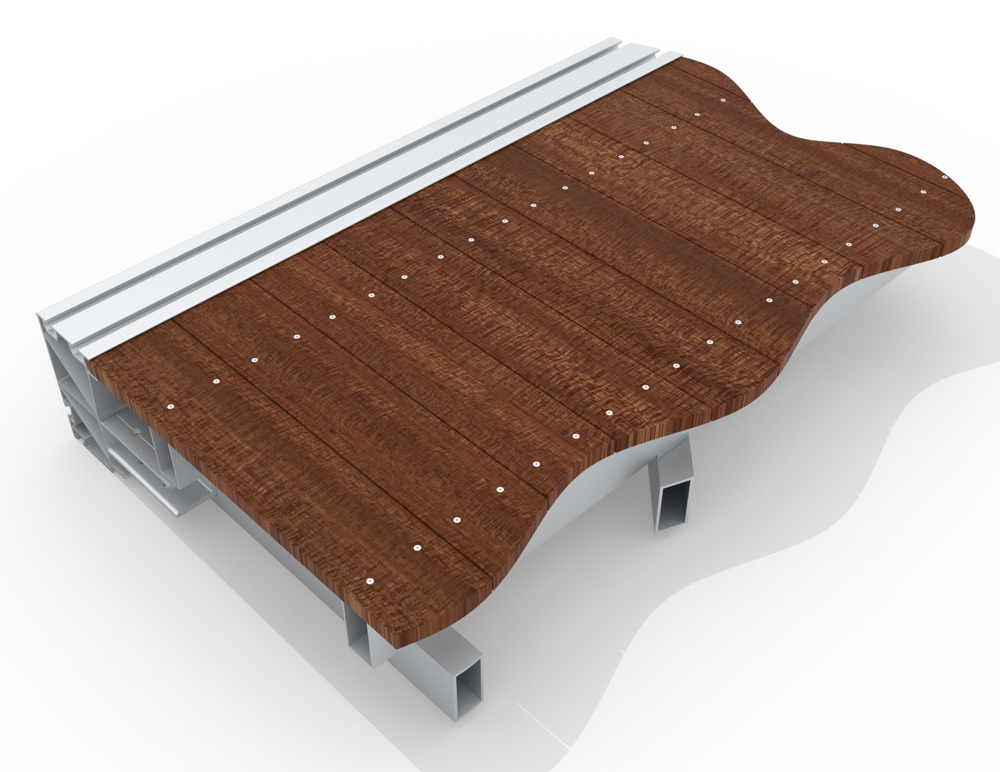

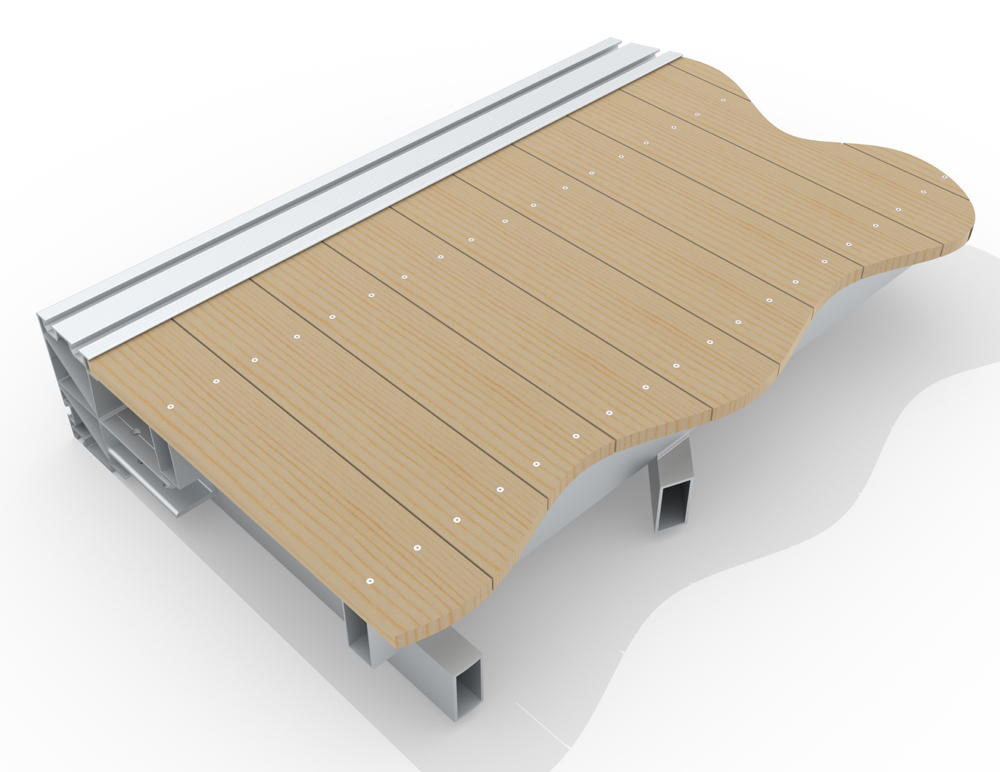

- Several decking options to choose from such as hardwood, composite, open-mesh and textured concrete panels.

- Internal or external aluminum pile guides with rollers or wear-pads.

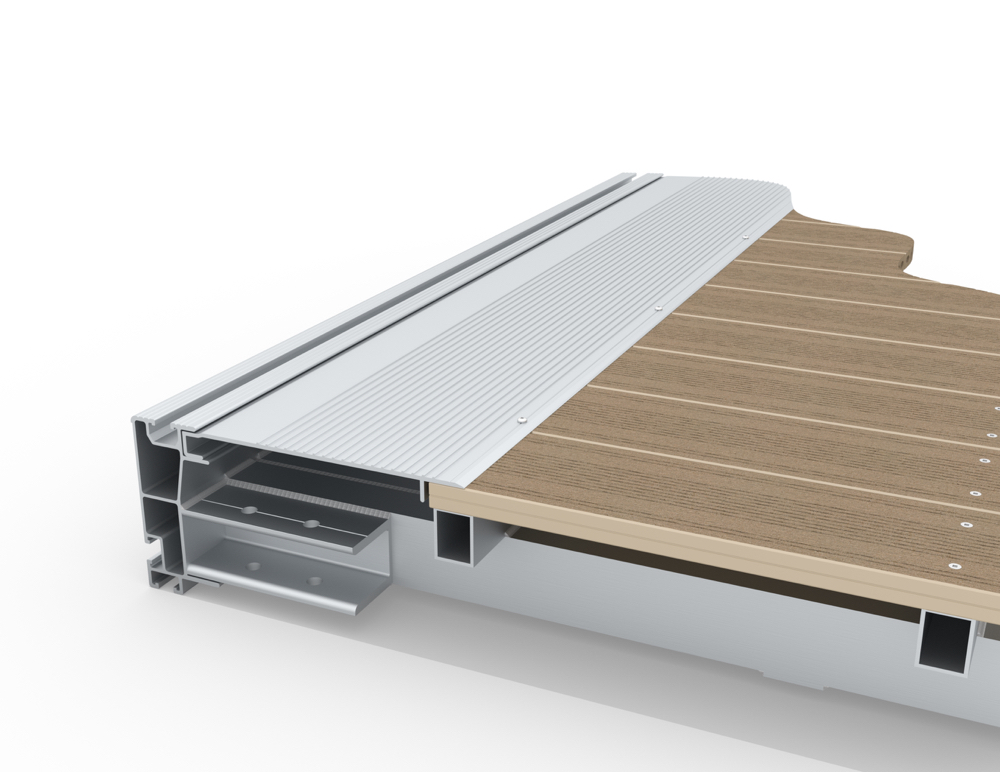

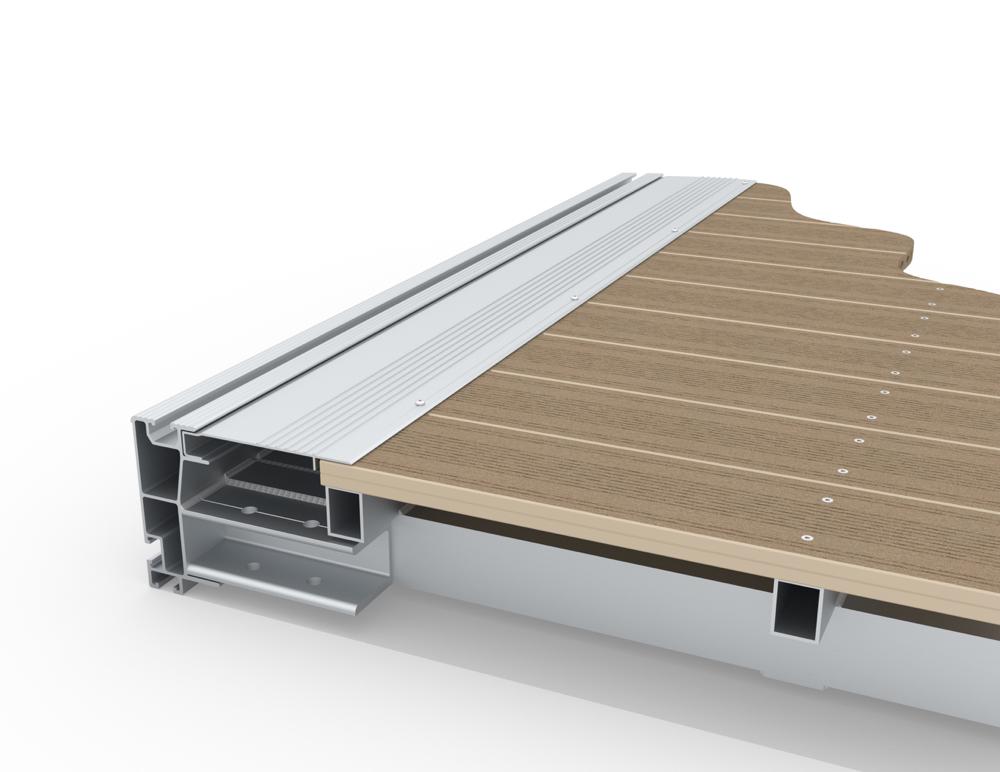

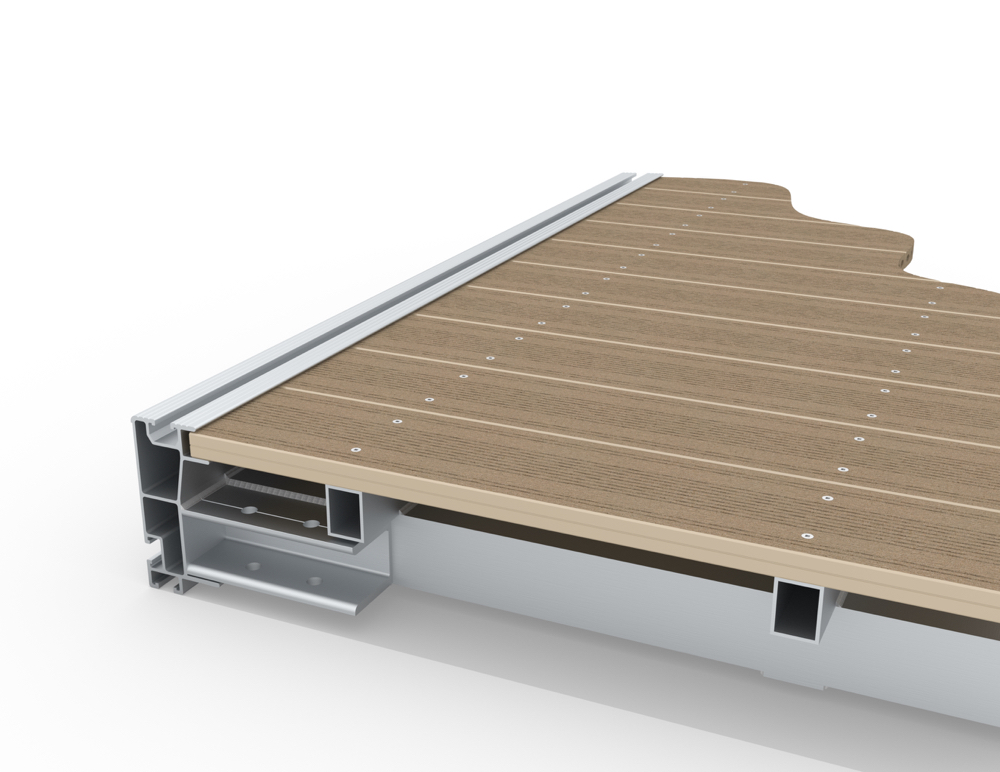

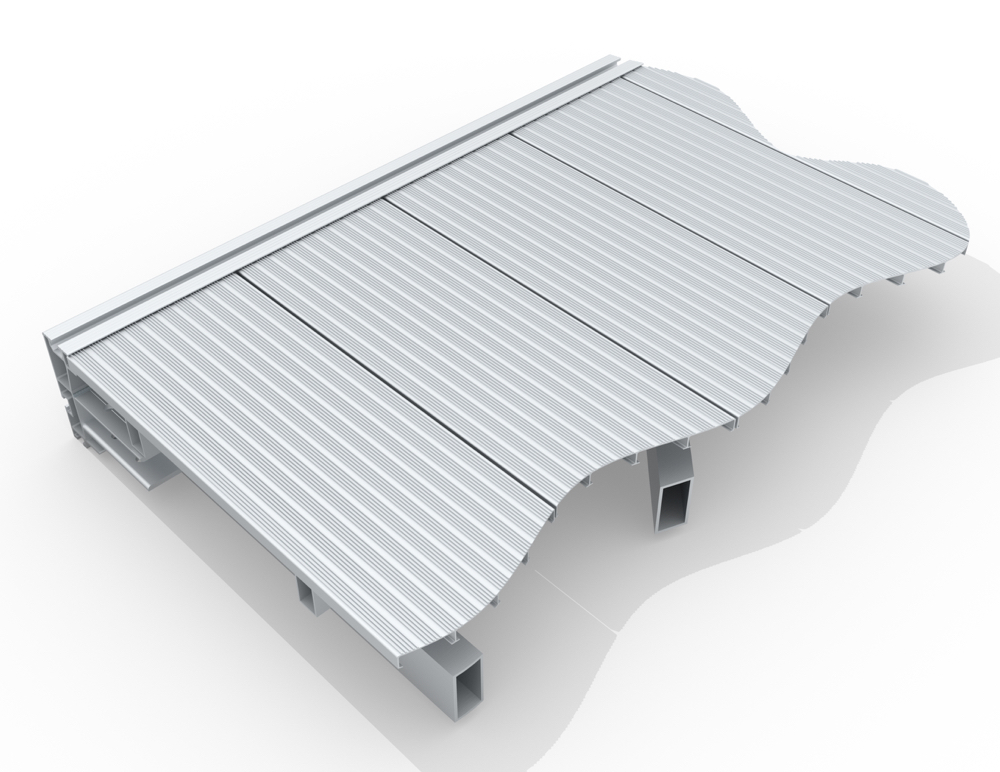

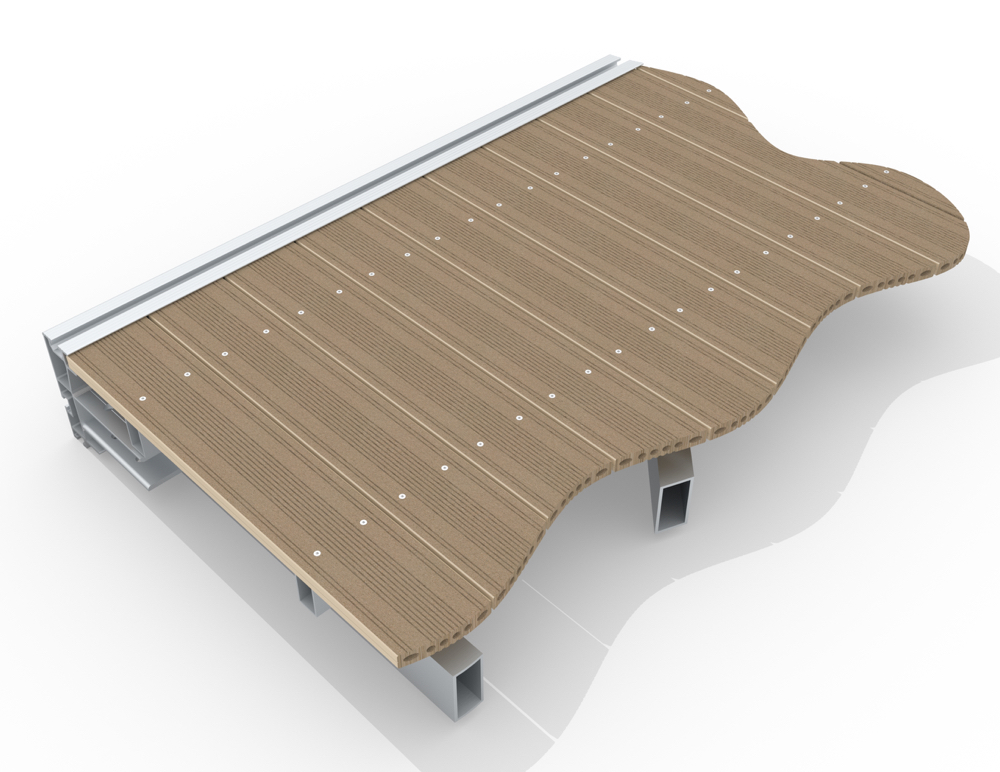

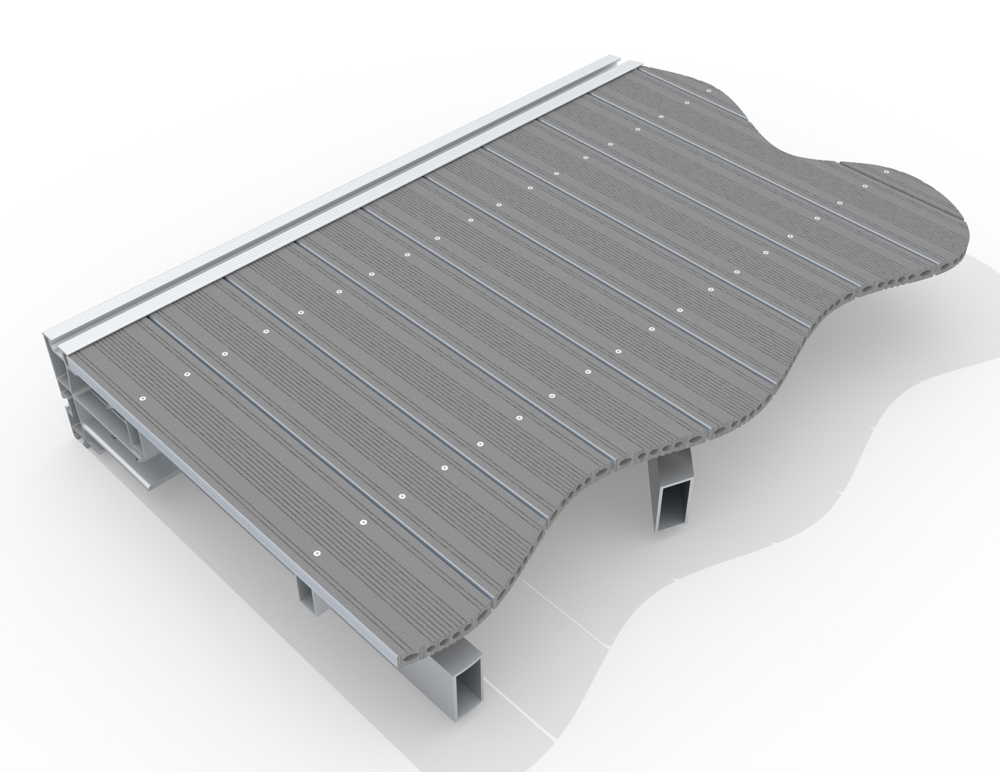

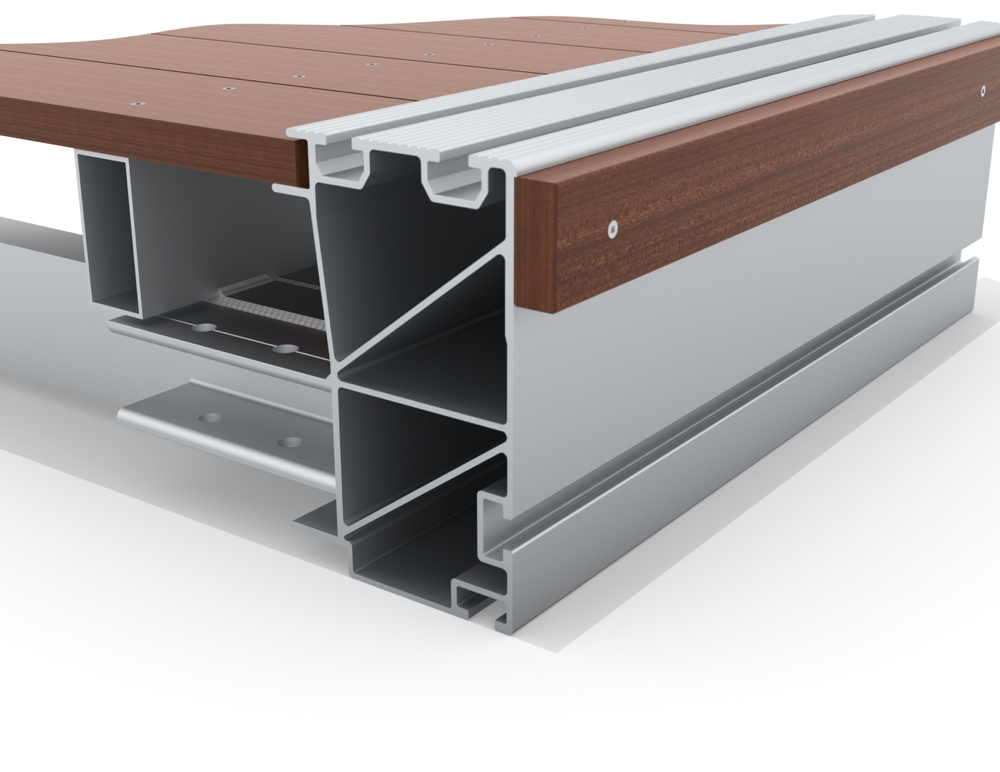

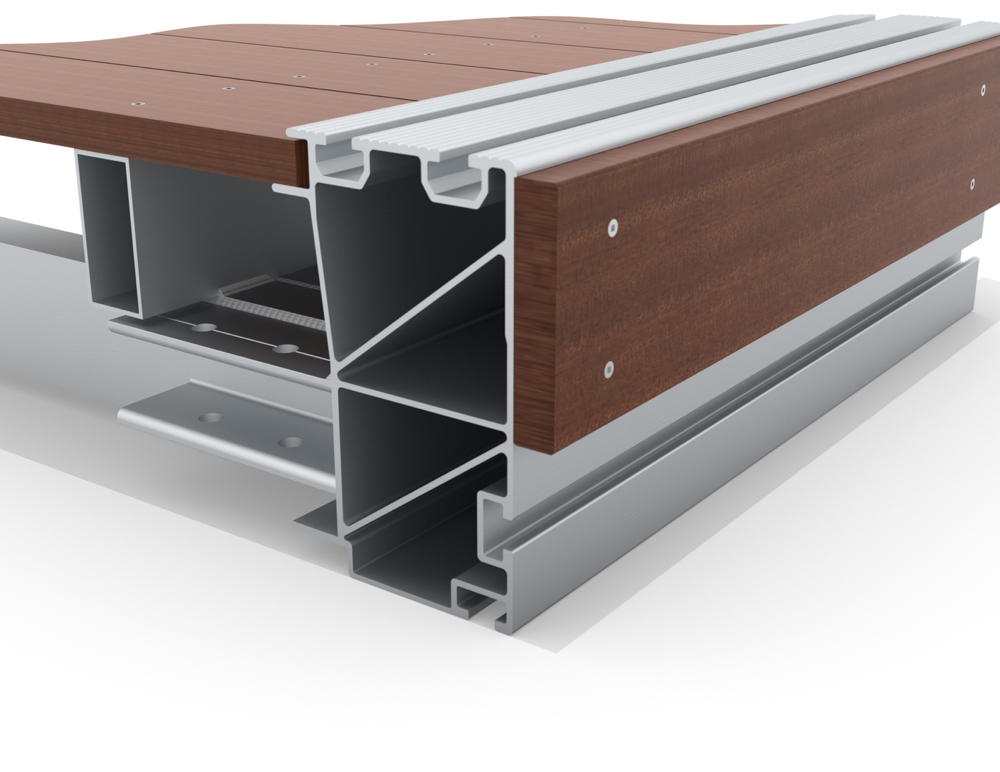

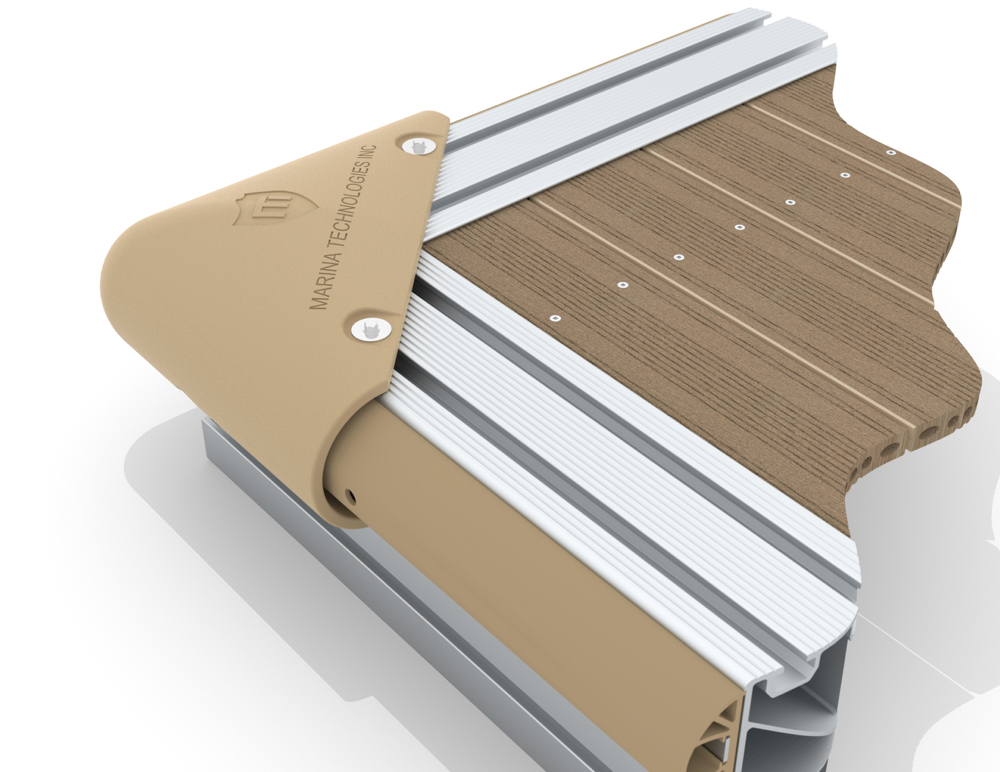

MTI-S222 SERIES ALUMINUM DOCKS

The MTI-S222 Series Aluminum Docks are constructed using Marine-Grade 6061-T6 Aluminum alloy and are designed and engineered to be very strong, maintenance free and elegant. The MTI-S222 Series is an advanced and versatile aluminum system that exceeds your expectations. Reconfiguration is easy thanks to the built-in top, bottom and lateral track system which allows for quick installation and repositioning of finger piers and cleats. The MTI-S222 dock sections are typically 40’ long and quickly connect together using strong noise-free high density rubber connectors with stainless steel hardware.

The MTI-S222 main docks are typically 4’, 6’, 8’ 10’ and 12’ wide. Single piece finger piers are typically 3’, 4’, 5’, 6,’ and 8’ wide and come rectangular or tapered.

The MTI-S222 Series Aluminum Docks also offer an optional unique floatation system using HI-STABILITY CONCRETE floats which greatly increases the dock mass, stability and loading capacity. This unique system combines the elegance of our aluminum series with the proven strength and stability of our concrete products. Each HI-STABILITY CONCRETE float weighs approximately 2,500 - 4,000 lbs. and offers extra resistance to tropical storms/hurricanes, ice, and floating debris. The stability is incredible and approaches the feel of an all concrete dock.

KEY Benefits:

- Proven strength, durability and stability.

- Polyethylene floats or unique HI-STABILITY CONCRETE floats.

- Noise-free, strong, and flexible rubber connectors allow the dock to perform in rough water conditions

- Built in growth potential - track System on all mains and fingers for quick assembly and reconfiguration - cleats, fingers and pile guides are easily repositioned also.

- Unique inner stainless-steel back plate within the track system for extra strong cleat connections.

- Quick and easy installation.

- 35 year design life with minimal maintenance.

- 18” - 24” standard freeboard.

- Internal utility routing and/or single or dual top-access utility troughs.

- Several fender options to choose from such as hardwood, composite, PVC, and rubber fenders with matching color corner bumpers.

- Several decking options to choose from such as hardwood, composite, open-mesh and textured concrete panels.

- Internal or external aluminum pile guides with rollers or wear-pads.

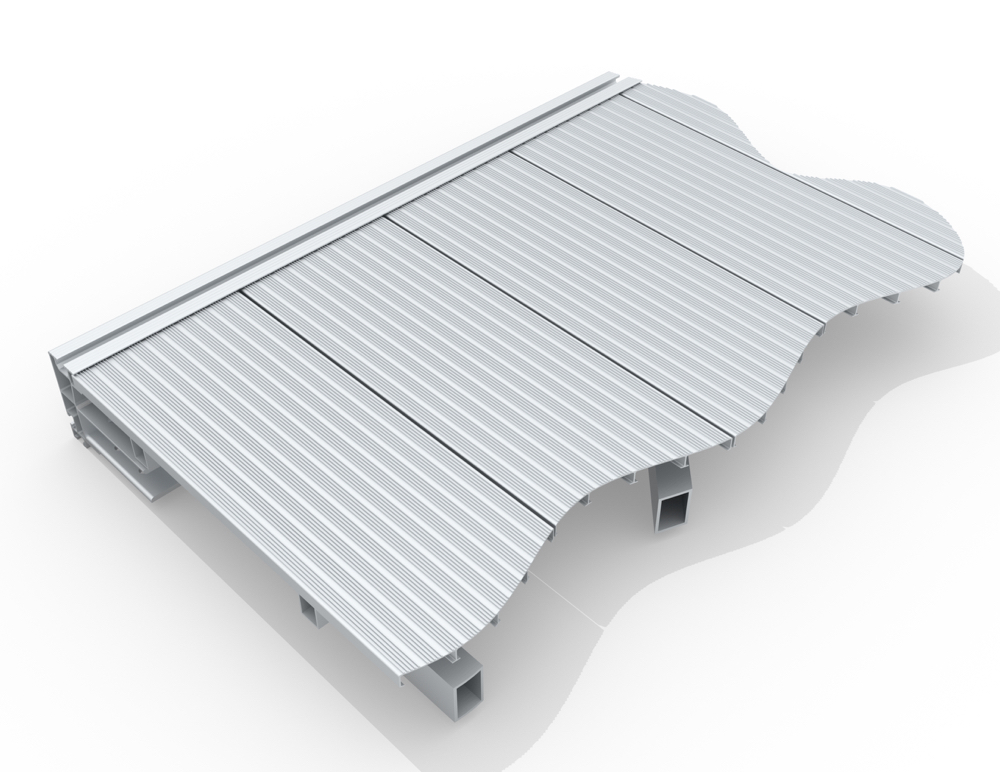

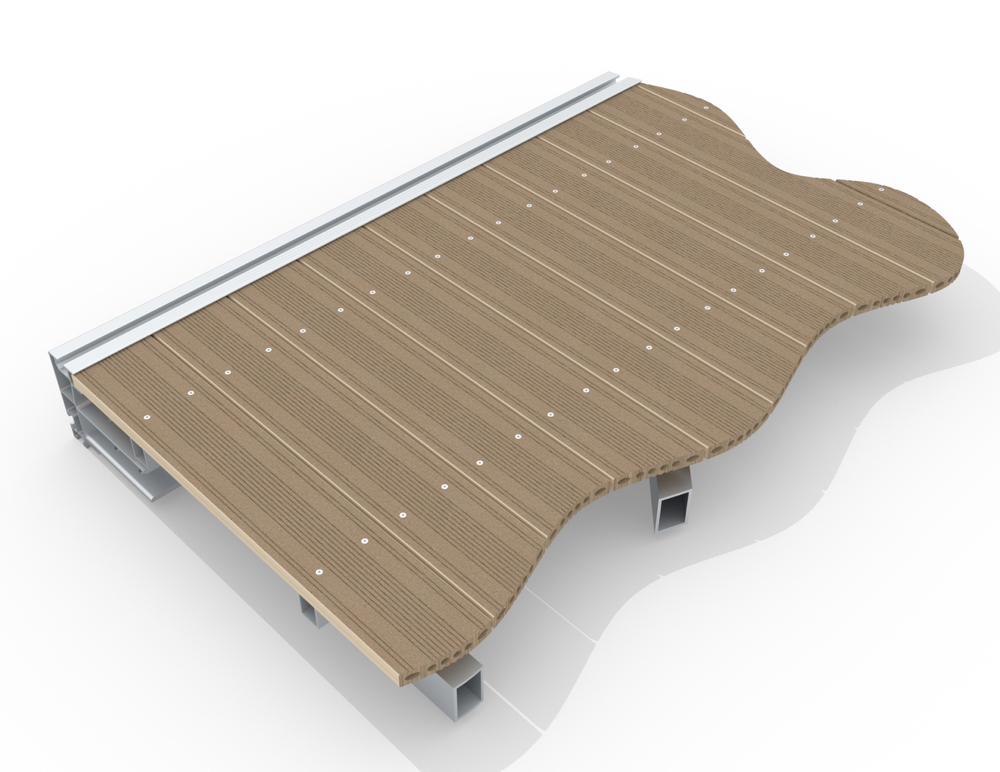

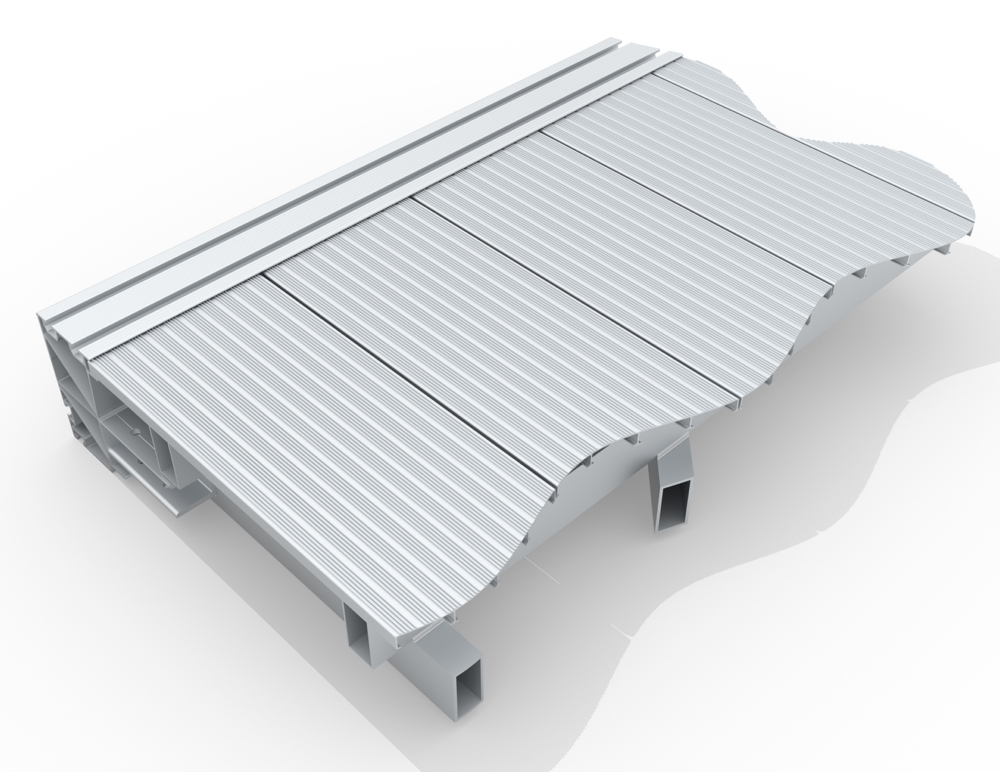

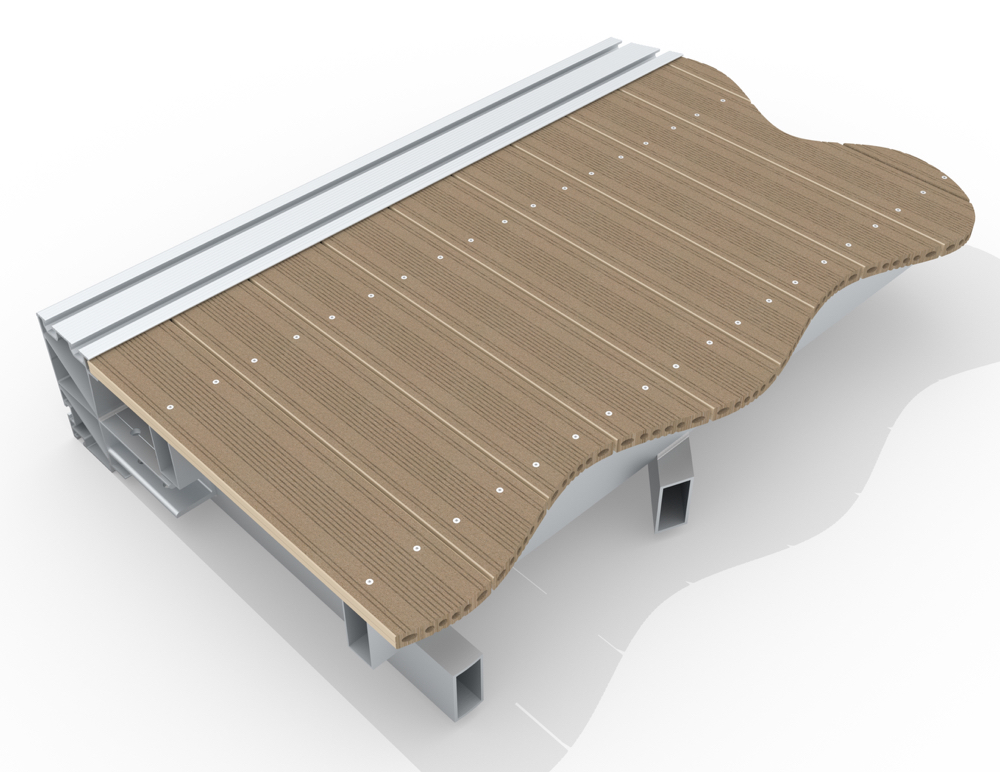

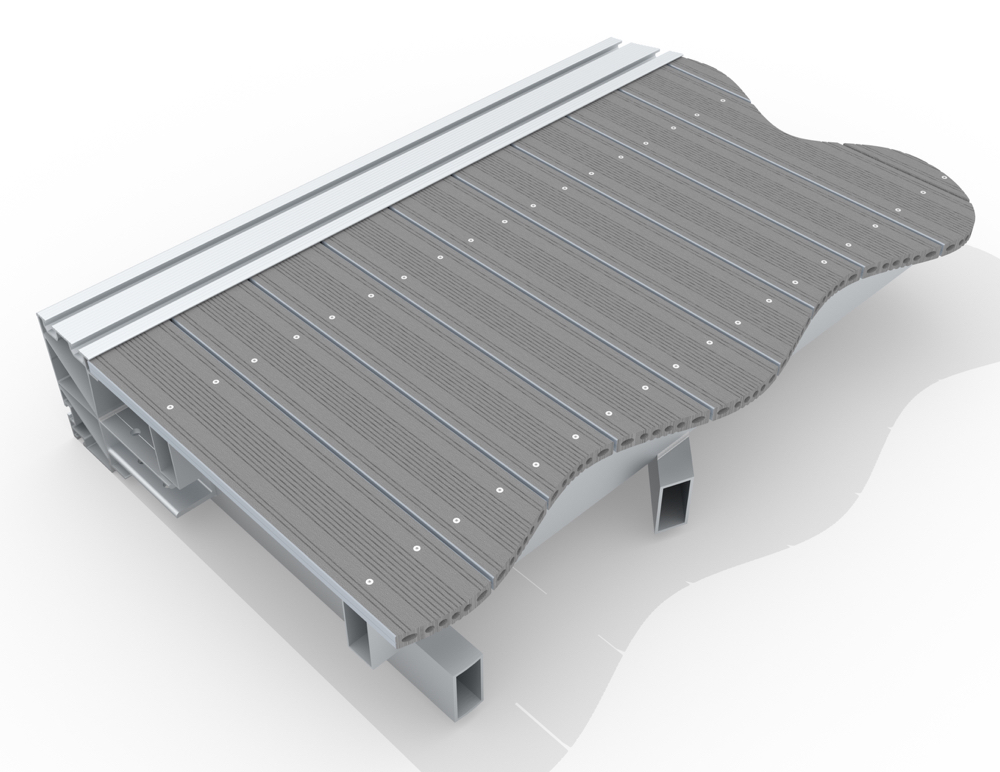

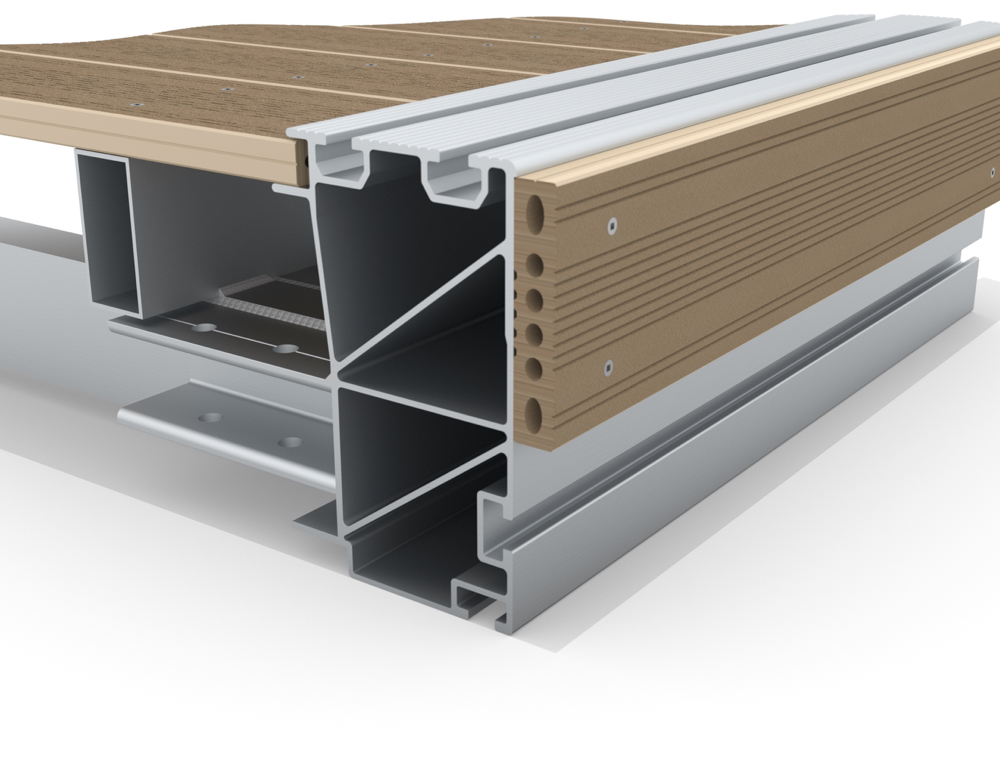

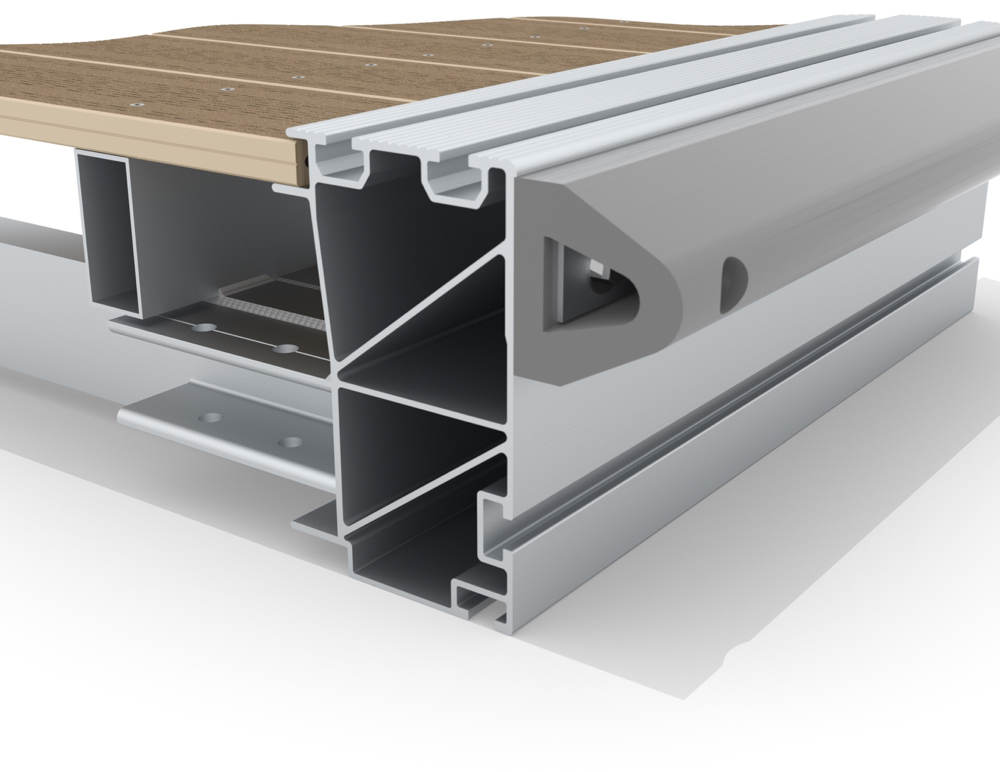

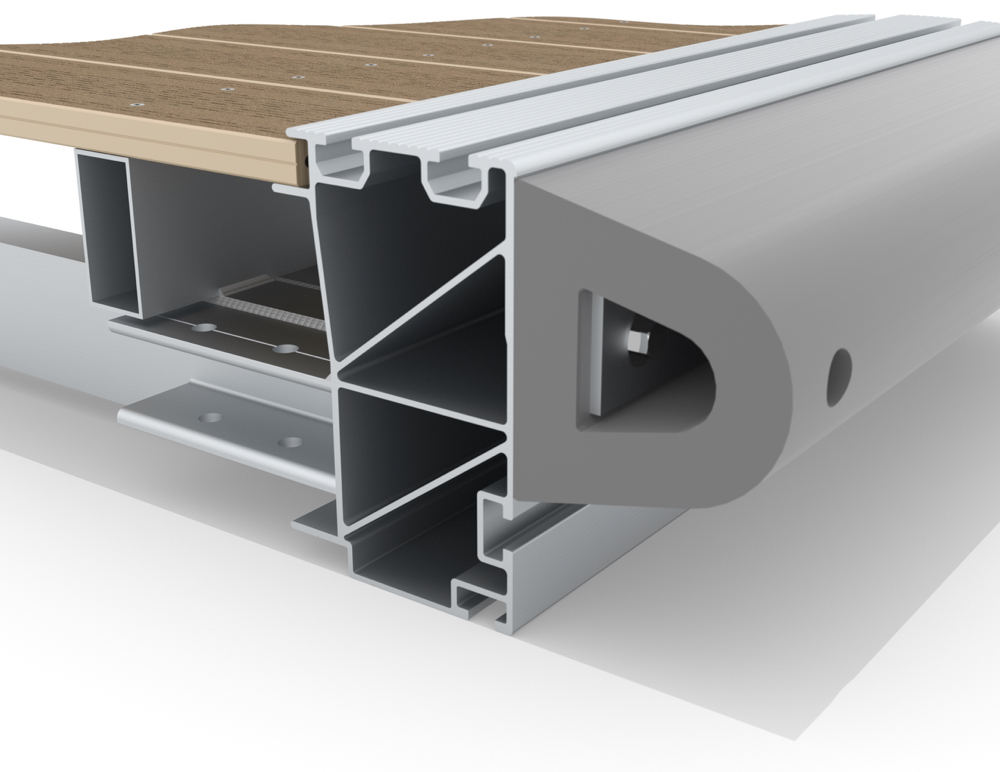

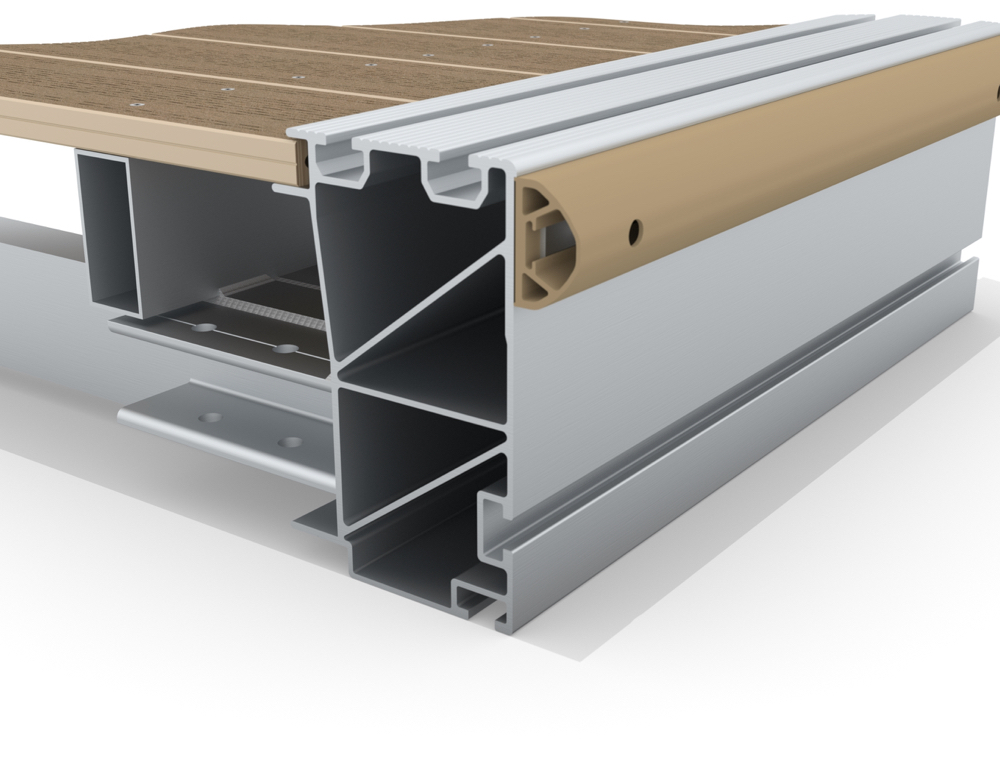

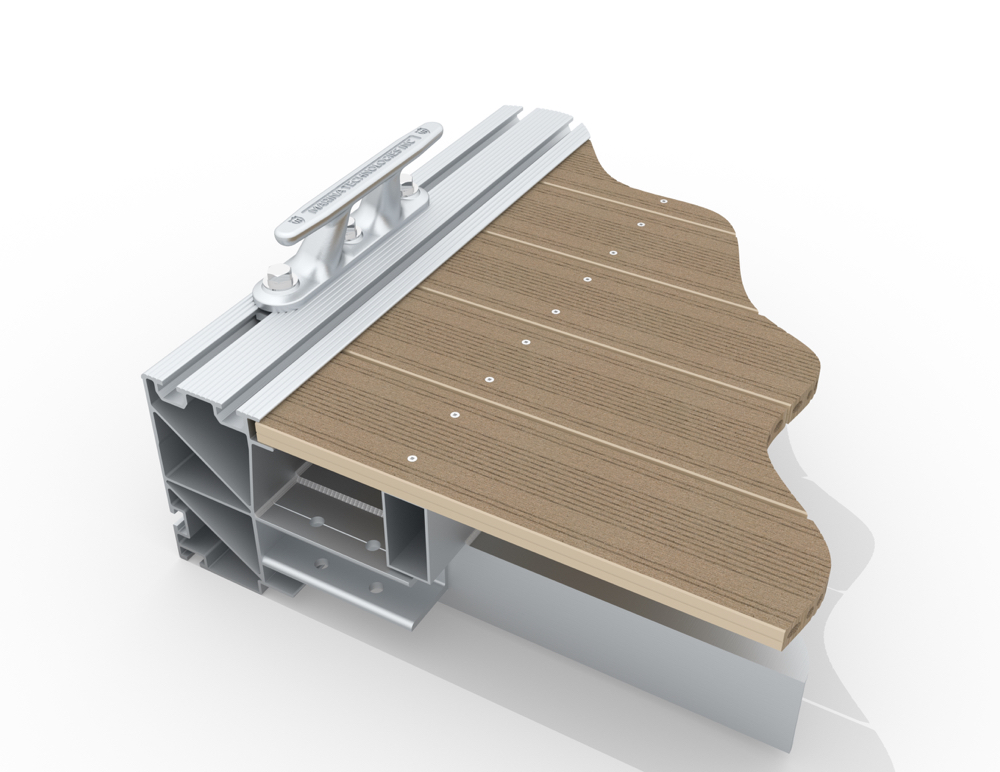

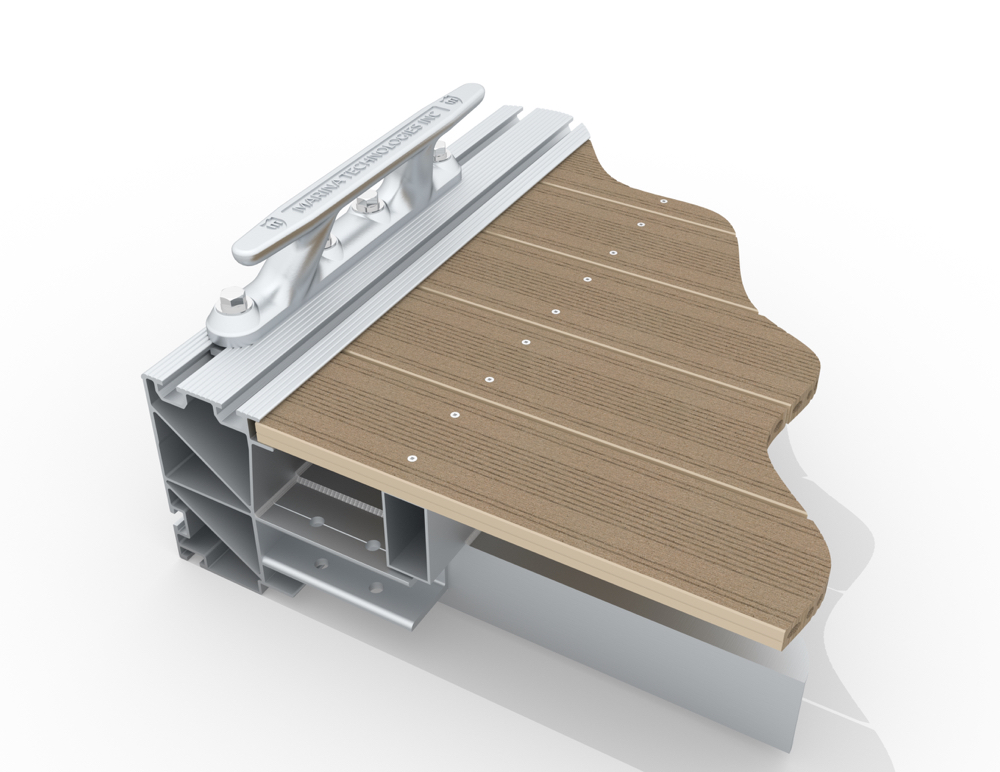

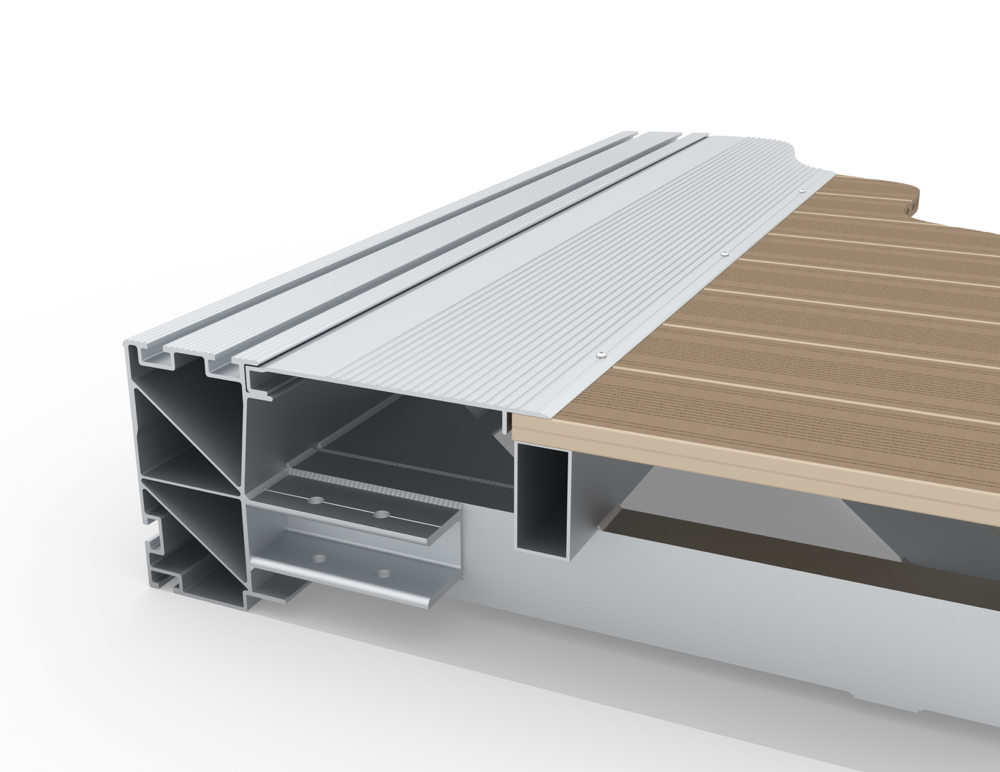

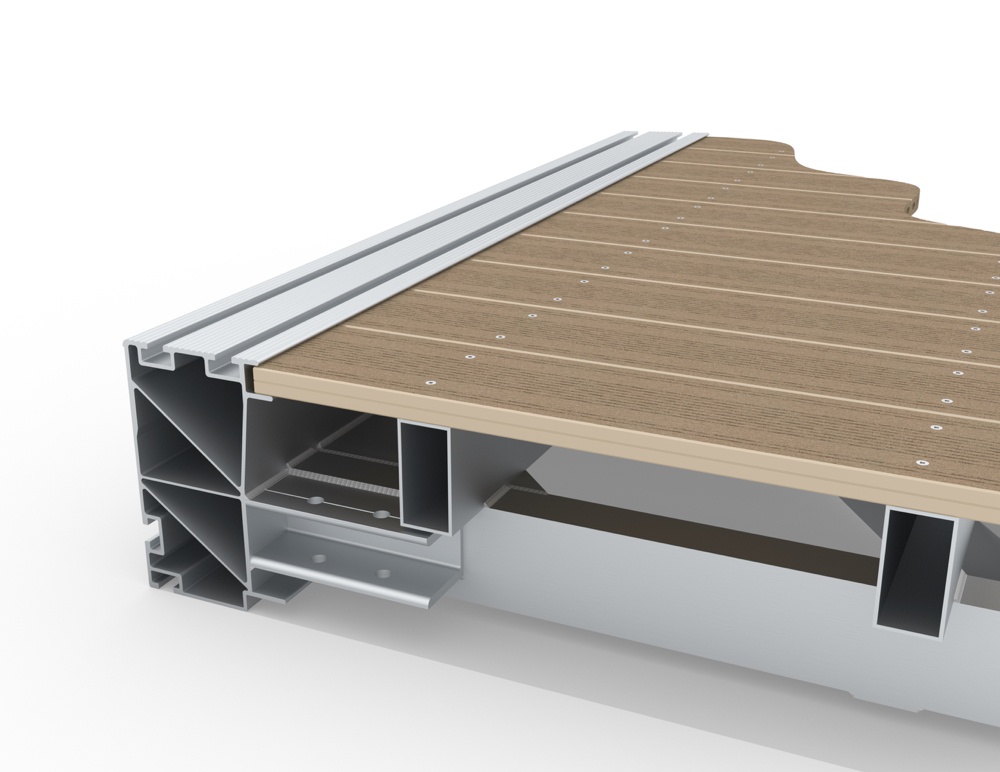

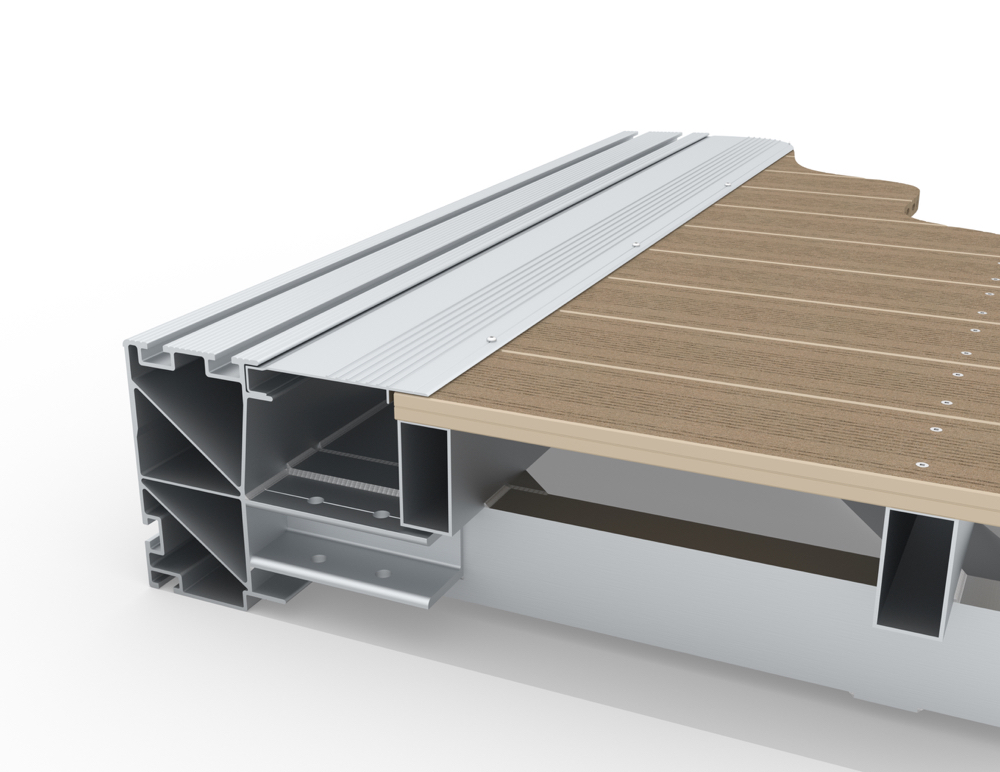

MTI-D260 SERIES ALUMINUM DOCKS

The MTI-D260 Series Aluminum Docks are constructed using Marine-Grade 6061-T6 Aluminum alloy and are designed and engineered to be extremely strong, maintenance free and elegant. The MTI-D260 Series is an advanced and versatile aluminum system that exceeds your expectations. Modification is simple thanks to the built-in dual top, bottom and lateral track system allows for quick installation and repositioning of finger piers and cleats. The MTI-D260 dock sections are typically 40’ long and quickly connect together using strong noise-free high density rubber connectors with stainless steel hardware.

The MTI-D260 main docks are typically 8’, 10’, 12’, 14’ and 16’ wide. Single piece finger piers are typically 4’, 5’, 6,’ 8’, 10’, and 12’ wide and come rectangular or tapered.

The MTI-D260 Series Aluminum Docks also offer an optional unique floatation system using HI-STABILITY CONCRETE floats which greatly increases the dock mass, stability and loading capacity. This unique system combines the elegance of our aluminum series with the proven strength and stability of our concrete products. Each HI-STABILITY CONCRETE float weighs approximately 2,500 - 4,000 lbs. and offers extra resistance to tropical storms/hurricanes, ice, and floating debris. The stability is incredible and approaches the feel of an all concrete dock.

KEY Benefits:

- Proven strength, durability and stability.

- Polyethylene floats or unique HI-STABILITY CONCRETE floats.

- Noise-free, strong, and flexible rubber connectors allow the dock to perform in rough water conditions

- Built in growth potential - track System on all mains and fingers for quick assembly and reconfiguration - cleats, fingers and pile guides are easily repositioned also.

- Unique inner stainless-steel back plate within the track system for extra strong cleat connections.

- Quick and easy installation.

- 35 year design life with minimal maintenance.

- 18” – 24” standard freeboard.

- Internal utility routing and/or single or dual top-access utility troughs.

- Several fender options to choose from such as hardwood, composite, PVC, and rubber fenders with matching color corner bumpers.

- Several decking options to choose from such as hardwood, composite, open-mesh and textured concrete panels.

- Internal or external aluminum pile guides with rollers or wear-pads.

MTI-ALUMINUM FIXED DOCKS

The MTI-Aluminum Fixed Docks are constructed using Marine-Grade 6061-T6 Aluminum alloy and are designed and engineered for pile supported structures. Spans can be up to 20’. The MTI-Aluminum Fixed Docks are an advanced, strong and versatile aluminum system that exceeds your expectations. Dock sections are typically 30’- 40’ long. Cleats, finger piers, railings and other accessories may be easily installed and reconfigured using the unique track system. Pre-assembled dock sections simply and quickly connect together and bolt to standard pile bents or on our aluminum beams.

Main docks are typically 4’ 6’, 8’, 10’ and 12’ wide. Single piece finger piers are typically 2’, 3’, 4,’, 5’ 6’ and 8’ wide and come either rectangular or tapered.

KEY Benefits:

- Extremely strong, durable, and stable.

- Systems may span up to 20’ between pile supports.

- Track System for quick and easy installation of cleats, finger piers and railings.

- Unique inner aluminum backing-plate within the track system for extra strong cleat connections.

- Quick and easy installation.

- 35 year design life with minimal maintenance.

- Internal utility routing and or single or dual top-access utility troughs.

- Several fender options to choose from such as hardwood, composite, PVC, and rubber with matching color corner bumpers.

- Several decking options such as hardwood, composite, open-mesh and textured concrete panels.

MTI-HYBRID SERIES DOCKS

The MTI-HYBRID Series is our unique and cost-efficient system consisting of floating concrete main docks coupled with our floating aluminum finger piers. This approach provides cost savings along with added features including adjustable cleats on the finger piers. This design concept may be used on any of our concrete docks and Wave Attenuating/Breakwater systems.

Aluminum finger piers may be 3’ - 8’ wide and come rectangular or tapered

MTI-ALUMINUM GANGWAYS AND PEDESTRIAN BRIDGES

MTI designs and manufactures beautiful and hi-quality gangways and bridges. Systems are designed to ADA standards – and beyond. All aluminum is Marine-Grade Alloy 6061-T6. We can totally customize your gangway system. Gangways may be straight or arched and a variety of other architectural features are available as well. Decking options include aluminum, hardwood, composite, or mesh.